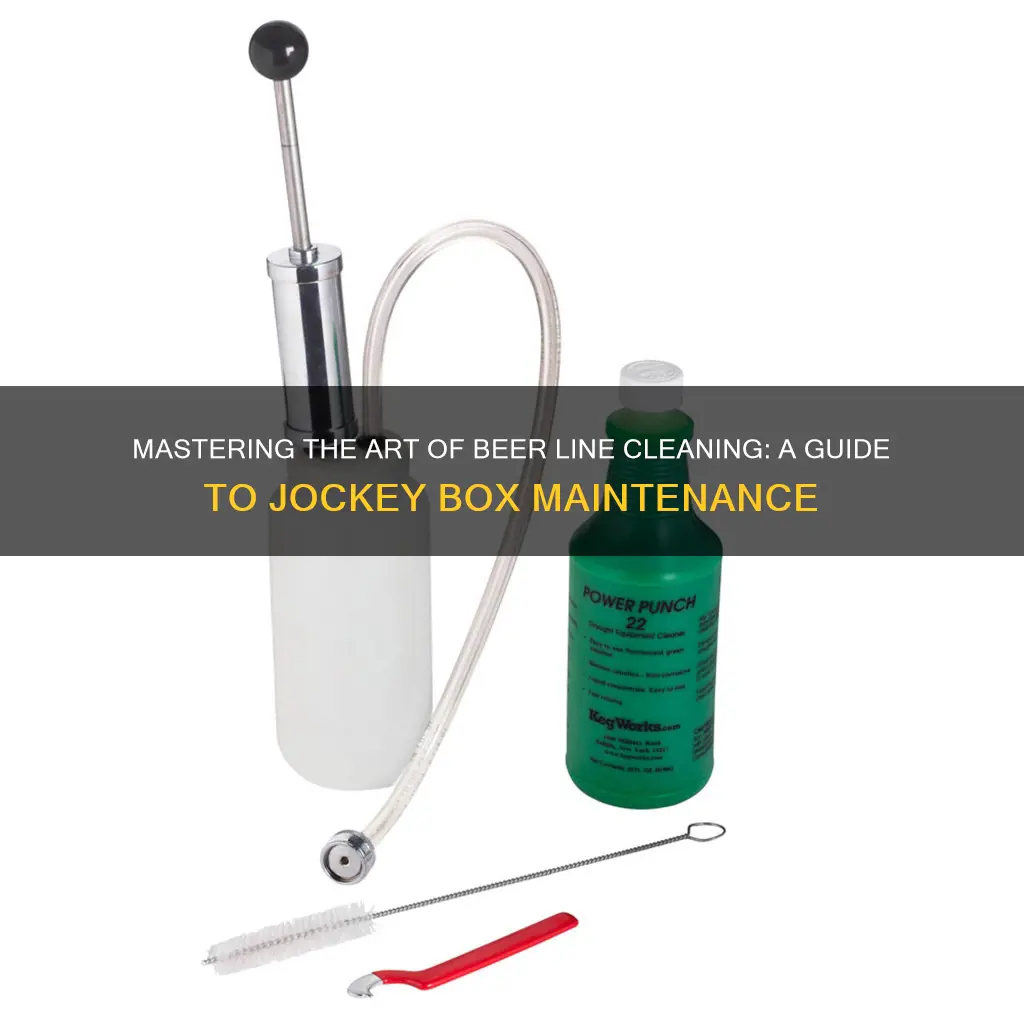

Cleaning beer lines in a jockey box is essential to ensure the best taste and quality of your beer. This process involves removing any residual beer, yeast, and bacteria that can accumulate over time, which can negatively impact the flavor and clarity of your beverage. By following a few simple steps, you can effectively clean and sanitize your beer lines, ensuring a consistent and enjoyable drinking experience. The process typically involves using a cleaning solution, such as a beer line cleaner, and a cleaning method, such as backflushing or a soak and flush technique.

| Characteristics | Values |

|---|---|

| Cleaning Frequency | Every 2-3 weeks or after each major event (e.g., a large party) |

| Cleaning Method | Use a cleaning solution specifically designed for beer lines, such as a 50/50 mix of white vinegar and warm water, or a commercial beer line cleaner. |

| Line Length | Measure the length of the beer line and adjust the cleaning solution accordingly. Longer lines may require more cleaning agent. |

| Temperature | Warm water is generally recommended to help dissolve grime and cleaning agents. |

| Pressure | Use a low-pressure cleaning method to avoid damaging the beer lines. A simple hand pump or a small air compressor can be used. |

| Rinsing | Thoroughly rinse the lines after cleaning to remove any residue. Use cold water and ensure no cleaning agent remains. |

| Maintenance | Regularly inspect the beer lines for any signs of wear and tear, and replace them if necessary. Keep the jockey box and lines covered when not in use to prevent dust and debris buildup. |

| Safety | Always wear gloves when handling cleaning solutions and ensure proper ventilation in the area. |

What You'll Learn

- Prepare the Jockey Box: Clean and sanitize the jockey box before starting the cleaning process

- Remove the Beer Line: Disconnect the beer line from the jockey box and any taps or faucets

- Use a Cleaning Solution: Pour a specialized beer line cleaning solution into the line and let it sit

- Rinse Thoroughly: Rinse the line multiple times with warm water to remove any residue

- Disassemble and Clean: Disassemble the line and clean each part with a brush and warm soapy water

Prepare the Jockey Box: Clean and sanitize the jockey box before starting the cleaning process

Before you begin the process of cleaning your beer lines in a jockey box, it is crucial to ensure that the jockey box itself is thoroughly prepared and ready for the cleaning procedure. This initial step is often overlooked but is essential for maintaining the quality and taste of your beer. Here's a detailed guide on how to prepare your jockey box:

Step 1: Empty the Jockey Box

Start by completely draining any remaining beer or water from the jockey box. This step is important to avoid any cross-contamination during the cleaning process. Remove the tap and any other components that are directly connected to the beer lines. This ensures that you can access all areas of the jockey box for a thorough clean.

Step 2: Disassemble the Jockey Box

Carefully take apart the jockey box, following the manufacturer's instructions. This might involve unscrewing or unclipping various parts such as the base, the cooling unit, and any additional compartments. Disassembly allows for a more comprehensive cleaning, ensuring that no dirt or residue is left behind.

Step 3: Clean the Interior

Once the jockey box is disassembled, it's time to clean its interior surfaces. Use a mild detergent or a specialized beer line cleaner. Apply the cleaner to a soft cloth or sponge and wipe down all the surfaces, including the walls, bottom, and any nooks or crannies. Pay extra attention to areas where beer residue or foam might accumulate. Rinse thoroughly with warm water to remove any detergent residue.

Step 4: Sanitize the Jockey Box

Sanitizing is a critical step to ensure the hygiene of your beer setup. Use a food-grade sanitizer specifically designed for food-contact surfaces. Follow the manufacturer's instructions for application. Typically, you'll need to spray or wipe the sanitizer onto all interior surfaces, ensuring complete coverage. Allow the sanitizer to sit for the recommended time before rinsing it off with clean water.

Step 5: Inspect and Dry

After cleaning and sanitizing, inspect the jockey box to ensure no dirt or residue remains. Rinse all parts again to remove any remaining sanitizer. Thoroughly dry the interior and exterior of the jockey box using a clean cloth. Moisture can lead to mold and bacteria growth, so ensure everything is completely dry before reassembling.

By following these steps, you'll create a clean and sanitized environment for your beer lines, ensuring the best possible taste and quality. This preparation process is a vital part of the overall cleaning routine and will contribute to the longevity of your beer equipment.

Boston Lager: A Classic American Lager Style

You may want to see also

Remove the Beer Line: Disconnect the beer line from the jockey box and any taps or faucets

To effectively clean your beer lines in a jockey box, it's crucial to start with a clean slate, and that begins with removing the beer line. This process ensures that you can access all areas of the line for thorough cleaning and maintenance. Here's a step-by-step guide on how to remove the beer line from the jockey box and any associated taps or faucets:

Step 1: Identify Connections

Locate the beer line's connections. The line typically connects to the jockey box at a fitting, often a quick-connect or a barbed fitting. Additionally, it will be connected to any taps or faucets you have installed. Identify these connections to ensure you can safely disconnect them.

Step 2: Disconnect from Jockey Box

Using a pair of pliers or a fitting wrench, carefully loosen and remove the fitting from the jockey box. Be gentle to avoid damaging the fitting or the jockey box's port. Ensure you have a clean, dry workspace to prevent any debris from falling into the fitting.

Step 3: Disconnect from Taps/Faucets

If you have taps or faucets connected to the beer line, repeat the process of loosening and removing the fittings. These connections are usually similar to the one on the jockey box. Carefully pull the beer line away from the taps or faucets to ensure a complete disconnection.

Step 4: Inspect and Clean

With the beer line removed, you now have access to the entire length of the line. Inspect it for any signs of wear, damage, or buildup. Use a small brush or a pipe cleaner to remove any debris or residue. If you notice significant buildup, consider using a mild detergent or a specialized beer line cleaner to ensure a thorough clean.

Step 5: Reattach and Test

Once you've cleaned the beer line, reattach it to the jockey box and any taps or faucets. Ensure all connections are tight and secure. Before using the beer line again, fill it with water and run it through a few cycles to flush out any cleaning agents and ensure there are no lingering odors or tastes.

By following these steps, you can effectively remove and clean your beer line, ensuring the best possible taste and quality from your beer. Regular maintenance and cleaning will help extend the life of your beer line and maintain the overall quality of your brewing setup.

Mastering the Art of Fermentation: Signs Your Beer is Done

You may want to see also

Use a Cleaning Solution: Pour a specialized beer line cleaning solution into the line and let it sit

To effectively clean your beer lines in a jockey box, using a specialized cleaning solution is a recommended method. This approach ensures a thorough and safe cleaning process, especially when dealing with the delicate components of a brewing system. Here's a step-by-step guide on how to utilize this cleaning solution:

Start by acquiring a high-quality beer line cleaning solution, which is specifically designed to break down and remove beer residue, yeast, and any built-up deposits. These solutions often contain enzymes and surfactants that are effective at dissolving and removing organic matter. Carefully pour the recommended amount of this cleaning solution into the beer line. The amount needed can vary depending on the length and condition of the line, so always refer to the product instructions for precise measurements. Once the cleaning solution is in the line, allow it to sit for a specified period. This waiting time is crucial as it gives the enzymes enough time to work their magic. Typically, this process can take anywhere from 15 minutes to an hour, depending on the product and the severity of the contamination. During this time, the cleaning solution will start to dissolve the beer residue and any other deposits, making it easier to flush out.

After the cleaning solution has done its work, it's time to rinse the line thoroughly. Use warm water to flush out any remaining cleaning solution and ensure that no residue is left behind. This step is essential to prevent any off-flavors or residual cleaning chemicals from affecting the taste of your beer. Rinse the line until the water runs clear, and consider using a beer line cleaner or a simple solution of warm water and dish soap to ensure a spotless finish.

By following this method, you can ensure that your beer lines are clean, free of any unwanted flavors, and ready to deliver the perfect pour every time. This technique is particularly useful for homebrewers and commercial breweries who want to maintain the quality and consistency of their beer. Remember, proper cleaning of beer lines is a critical aspect of the brewing process, and using a specialized cleaning solution is a reliable way to achieve this.

Binge-Drinking Blues: Beer Limits and the Legal Line

You may want to see also

Rinse Thoroughly: Rinse the line multiple times with warm water to remove any residue

Rinsing the beer lines is a crucial step in the cleaning process, ensuring that no beer residue or buildup remains. This step is often overlooked but is essential for maintaining the quality of your brew and the overall taste of the beer. Here's a detailed guide on how to effectively rinse the lines:

Begin by filling the jockey box with warm water, ensuring it's not too hot to avoid any potential damage to the equipment. The water temperature should be around 100-110°F (38-43°C). This warm water will help to dissolve and remove any beer residue effectively. Start by running the water through the line slowly, allowing it to flow from the tap to the pitcher or glass. This initial rinse helps to dislodge any loose particles and prepares the line for more thorough cleaning.

After the initial warm water rinse, it's time for multiple thorough rinses. Fill the jockey box again with warm water and run it through the line several times. Each pass should be slow and deliberate, ensuring that all parts of the line are covered. The goal is to remove any remaining beer residue, which can include sugars, yeast, and other impurities. By running the water multiple times, you're essentially flushing out any leftover beer, leaving the line clean and ready for the next brew.

Pay close attention to the connections and joints of the line. These areas can accumulate residue and require extra care. Use a gentle back-and-forth motion when rinsing these parts to ensure no residue is left behind. You can also use a small brush or a cleaning tool to gently scrub these areas, ensuring a thorough clean. The more thorough your rinsing process, the better the overall taste and quality of your beer will be.

Remember, the key to successful rinsing is patience and consistency. Take your time and ensure that all parts of the line are properly rinsed. This step might seem tedious, but it's an essential part of the brewing process, ensuring that your beer is always fresh and delicious.

Foster's Lager: Light or Dark? Unveiling the Mystery

You may want to see also

Disassemble and Clean: Disassemble the line and clean each part with a brush and warm soapy water

To ensure your beer lines in a jockey box are clean and ready for the next brew, disassembly and thorough cleaning are essential. This process involves carefully taking apart the line to access all areas, including the inner and outer surfaces, to remove any built-up residue and prevent off-flavors in your beer. Here's a step-by-step guide to achieving this:

Start by disconnecting the beer line from the jockey box and any taps or faucets it is connected to. This step is crucial for a safe and effective cleaning process. Once disconnected, carefully remove the beer line from the jockey box. Inspect the line for any visible dirt, residue, or blockages. Use a soft-bristled brush to gently scrub the outer surface of the line, removing any loose particles. This initial step helps to loosen and remove surface-level contaminants.

Next, focus on the inner part of the line. This is where the magic happens, as it's the primary path for beer flow. To access the inner surface, you'll need to disassemble the line further. Carefully cut or carefully unscrew any connections or fittings that secure the inner and outer parts of the line. Be cautious not to damage the fittings during this process. Once the inner and outer sections are separated, you can now clean each component thoroughly.

Take the inner and outer parts of the line and immerse them in warm soapy water. Use a soft-bristled brush or a specialized beer line cleaning brush to scrub the inner surface of the line, paying extra attention to the areas where the line connects to the jockey box and any other fittings. The warm soapy water helps to dissolve and remove any stubborn residue, while the brush ensures a thorough clean. Rinse the line thoroughly with warm water to remove any soap residue.

For a more thorough clean, consider using a specialized beer line cleaning solution or a mild detergent mixed with warm water. This step ensures that you're not just removing visible dirt but also addressing any potential bacteria or mineral deposits that may affect the beer's taste. After cleaning, allow the line to air dry completely before reassembling and reattaching it to your jockey box and other brewing equipment.

By following these steps, you'll ensure that your beer lines are clean, free of contaminants, and ready to deliver the perfect pour every time. Regular maintenance and cleaning will also extend the life of your brewing equipment and enhance the overall quality of your beer.

The Beer Line Conundrum: To Clean or Not to Clean?

You may want to see also

Frequently asked questions

It is recommended to clean your beer lines every 2-4 weeks, or more frequently if you notice any off-flavors or a buildup of residue. Regular cleaning ensures the beer remains fresh and flavorful.

A common and effective method is to use a cleaning solution specifically designed for beer lines, such as a 50/50 mix of bleach and water. This solution helps eliminate bacteria and odors. After cleaning, rinse the lines thoroughly with warm water to remove any residue.

While a pressure washer can be used, it should be done with caution. High-pressure water can damage the inner lining of the beer lines. It's best to use a lower-pressure setting and ensure the washer is not too close to the connections to avoid any potential issues.

Proper storage and handling are key. Always keep the jockey box and beer lines clean and free of debris. Use clean, sanitized tools and containers when transferring beer. Additionally, consider using a carbon filter or carbon block to further reduce the risk of contamination and improve the taste of your beer.