Fed-batch beer fermentation is a specialized brewing technique that involves a controlled process of yeast fermentation. This method is used to optimize the beer-making process by gradually feeding a limited amount of nutrients to the yeast culture during the fermentation phase. By carefully managing the yeast's environment, brewers can enhance the flavor, aroma, and overall quality of the beer, resulting in a more consistent and desirable product. This technique is particularly useful for producing beers with complex flavors and high alcohol content, as it allows for precise control over the fermentation process.

| Characteristics | Values |

|---|---|

| Definition | Fed-batch fermentation is a process in brewing where the yeast is gradually introduced to the wort (the sugary liquid extracted from malted grains) in stages, rather than all at once. |

| Advantages | 1. Improved yeast health and vitality, leading to higher fermentation efficiency. 2. Enhanced flavor and aroma development due to longer fermentation times. 3. Reduced risk of off-flavors and infections. |

| Yeast Usage | Typically uses a specific yeast strain, often a high-alcohol-tolerant yeast like Brettanomyces or a specialty ale yeast. |

| Process | The wort is initially inoculated with a small amount of yeast, allowing it to acclimate and activate. Then, additional yeast is added in fed batches at regular intervals, providing a controlled environment for fermentation. |

| Timeframe | Fed-batch fermentation can take longer than traditional batch fermentation, often spanning several days to a week or more. |

| Temperature Control | Precise temperature control is crucial during fed-batch fermentation to optimize yeast activity and prevent temperature-sensitive compounds from degrading. |

| Applications | Commonly used in the production of specialty beers, such as Belgian ales, wild ales, and certain styles of wheat beers. |

| Challenges | Requires careful monitoring and precise control of yeast feeding schedules and temperatures. |

| Benefits for Beer Quality | Results in beers with complex flavors, higher alcohol content, and unique characteristics that are often sought after by craft beer enthusiasts. |

What You'll Learn

- Fed-batch fermentation: A controlled process where nutrients are gradually added to the beer during fermentation

- Nutrient management: Precise control of nutrient addition rates to optimize yeast performance and beer quality

- Yeast adaptation: Yeast acclimates to nutrient changes, enhancing fermentation efficiency and flavor development

- Batch control: Automated systems regulate temperature, pH, and oxygen levels for consistent fermentation outcomes

- Quality assurance: Monitoring and adjusting fermentation parameters to ensure beer meets desired standards and consistency

Fed-batch fermentation: A controlled process where nutrients are gradually added to the beer during fermentation

Fed-batch fermentation is a sophisticated technique employed in the brewing industry to optimize the fermentation process of beer. This method involves a controlled and precise approach to nutrient management, where ingredients are added gradually to the beer during the fermentation stage. By carefully monitoring and adjusting the nutrient levels, brewers can fine-tune the fermentation process, resulting in a more consistent and high-quality beer product.

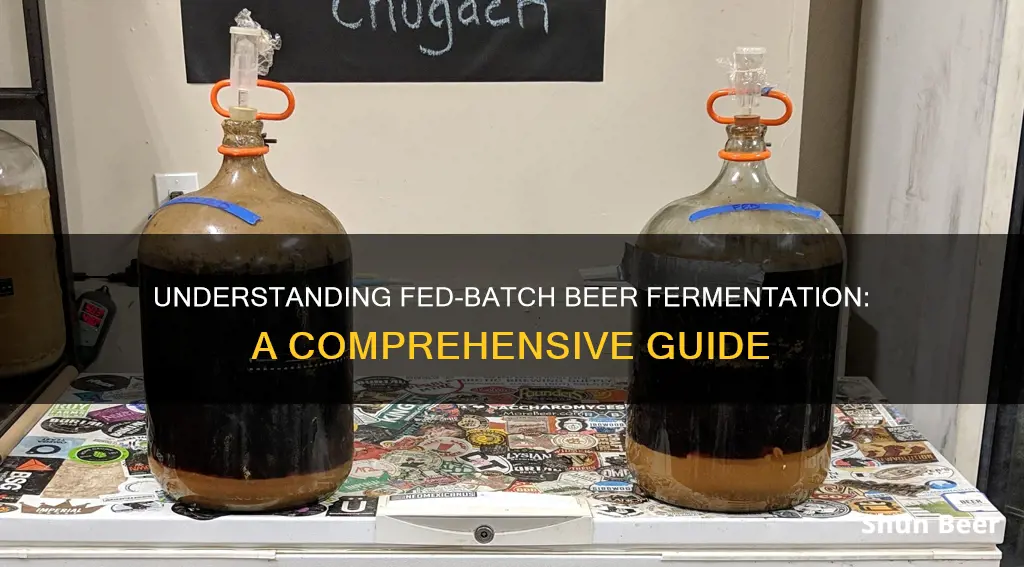

The process begins with an initial batch of beer, which serves as the foundation for the fed-batch system. This initial batch is prepared with a specific amount of malt, hops, and other ingredients, ensuring a balanced and flavorful base. Once the initial fermentation is complete, the real magic begins with the fed-batch process. Here, nutrients such as sugars, amino acids, and vitamins are introduced in a controlled manner. These nutrients act as food for the yeast, providing the necessary energy for continued fermentation. The key advantage of this approach is the ability to precisely control the fermentation environment, allowing brewers to manipulate the yeast's activity and influence the beer's final characteristics.

Gradual addition of nutrients is a critical aspect of fed-batch fermentation. Instead of adding all the nutrients at once, they are introduced in stages, mimicking the natural process of yeast growth and metabolism. This controlled feeding strategy ensures that the yeast population remains stable and active throughout the fermentation. By carefully monitoring the yeast's activity and adjusting the nutrient levels, brewers can prevent issues like off-flavors, cloudiness, or even yeast death, which could negatively impact the beer's quality.

One of the significant benefits of fed-batch fermentation is the enhanced control it offers over the beer's final attributes. Brewers can manipulate the fermentation parameters, such as temperature, pH, and oxygen levels, to influence the beer's flavor, aroma, and overall character. This level of control is particularly valuable for creating unique and experimental beer styles, allowing brewers to push the boundaries of traditional brewing methods. Moreover, fed-batch fermentation can contribute to a more efficient brewing process, reducing waste and optimizing resource utilization.

In summary, fed-batch fermentation is a meticulous and controlled process that revolutionizes beer production. By gradually adding nutrients during fermentation, brewers can fine-tune the yeast's activity, resulting in a more consistent and desirable beer product. This technique empowers brewers to experiment with flavors, aromas, and styles, pushing the boundaries of what's possible in the world of craft beer. With its ability to provide precise control and customization, fed-batch fermentation is undoubtedly a valuable tool in the hands of passionate brewers.

Uncorking Ancient Fermentation: A Journey Through Time's Brewed Delights

You may want to see also

Nutrient management: Precise control of nutrient addition rates to optimize yeast performance and beer quality

The concept of fed-batch fermentation is an innovative approach to brewing beer, offering precise control over the nutrient addition process, which is crucial for optimizing yeast performance and beer quality. This method involves a carefully planned and controlled feeding strategy, where nutrients are added in a specific sequence and at predetermined rates. By doing so, brewers can fine-tune the yeast's environment, ensuring it operates at its peak efficiency.

In traditional batch brewing, nutrients are typically added all at once, which can lead to rapid yeast growth and potential issues. However, fed-batch fermentation takes a more measured approach. It begins with an initial nutrient feed, providing the yeast with the necessary resources to start the fermentation process. This initial feed is crucial as it sets the foundation for the entire fermentation, influencing the yeast's activity and the beer's final characteristics.

The key to success in fed-batch beer fermentation lies in the precise control of nutrient addition rates. Brewers must carefully calculate and adjust the feeding rates based on various factors, including yeast strain, desired beer style, and fermentation conditions. For instance, a slower, more gradual nutrient addition might be employed for delicate, high-alcohol beers to prevent excessive yeast activity. Conversely, a rapid feed could be used for faster-fermenting styles to optimize yeast performance.

During the fermentation process, regular monitoring of nutrient levels is essential. This involves taking samples and analyzing the beer's composition to ensure the yeast has the required nutrients without being overloaded. Over-feeding can lead to off-flavors and potential yeast stress, while under-feeding may result in incomplete fermentation. Thus, a delicate balance must be struck to maintain optimal yeast health and beer quality.

Additionally, the fed-batch method allows brewers to manipulate the fermentation environment, such as adjusting temperature and oxygen levels, to further enhance yeast performance. This comprehensive control over the brewing process enables the production of high-quality beers with consistent and desirable attributes. By optimizing yeast activity through precise nutrient management, brewers can achieve superior beer flavors, improved clarity, and enhanced overall beer quality.

Secondary Fermentation: Unlocking Flavor Potential in Kit Beers

You may want to see also

Yeast adaptation: Yeast acclimates to nutrient changes, enhancing fermentation efficiency and flavor development

Yeast adaptation is a crucial process in the art of brewing, especially when it comes to fed-batch beer fermentation. This technique involves gradually adjusting the yeast to the specific conditions and nutrients present in the fermentation vessel, which can significantly impact the final beer's quality and characteristics. By acclimating the yeast, brewers can optimize fermentation efficiency and unlock a more nuanced flavor profile.

In fed-batch fermentation, the yeast is introduced to a controlled environment where the nutrients, such as sugars and amino acids, are added in a precise manner. This process mimics the natural yeast-nutrient relationship found in wild fermentation but in a more controlled and predictable setting. The key to success lies in the yeast's ability to adapt to these changing conditions. As the yeast encounters different nutrient levels, it undergoes a series of metabolic adjustments. It learns to utilize the available resources efficiently, producing the desired beer components while minimizing off-flavors and aromas.

During this adaptation phase, yeast cells undergo a transformation. They develop a higher tolerance for the specific nutrients present in the batch, allowing for a more efficient fermentation process. For instance, if the batch contains a higher concentration of maltose, the yeast will adapt to produce more enzymes to break down this complex carbohydrate, resulting in a more complete fermentation. This adaptation also enables the yeast to produce a wider range of flavor compounds, contributing to the beer's overall character.

The art of yeast adaptation requires precision and an understanding of the yeast's behavior. Brewers must carefully monitor the yeast's growth and activity, making adjustments as needed. This might involve altering the temperature, pH, or nutrient ratios to guide the yeast's adaptation process. By doing so, brewers can ensure that the yeast is well-prepared for the specific fermentation conditions, leading to a more consistent and desirable beer outcome.

In summary, yeast adaptation in fed-batch beer fermentation is a delicate process that allows brewers to fine-tune the beer's flavor and efficiency. It empowers the yeast to become a master of its environment, producing a beer that showcases the brewer's skill and creativity. This technique is a testament to the intricate relationship between yeast and beer, where the yeast's adaptability is key to unlocking the full potential of the brewing process.

Uncorking the Mystery: Straw's Magic in Beer

You may want to see also

Batch control: Automated systems regulate temperature, pH, and oxygen levels for consistent fermentation outcomes

The concept of batch control in the context of beer fermentation involves the precise management of various parameters to ensure consistent and high-quality fermentation outcomes. This process is particularly crucial in the production of craft beers, where achieving a specific flavor profile and character is essential. At the heart of batch control are automated systems designed to regulate and maintain optimal conditions for yeast fermentation.

Temperature control is a critical aspect of batch control. Yeast, the microorganism responsible for fermentation, is highly sensitive to temperature changes. Automated temperature control systems monitor and adjust the temperature of the fermentation vessel to maintain a consistent and ideal range. This is typically achieved through the use of heating or cooling coils, ensuring that the yeast performs optimally throughout the fermentation process. By keeping the temperature stable, brewers can enhance the efficiency of fermentation and promote the desired flavor development.

PH regulation is another vital component of batch control. The pH level of the fermentation medium directly influences the yeast's activity and the overall beer quality. Automated pH control systems continuously measure and adjust the pH to maintain an optimal range. This is crucial as deviations from the ideal pH can impact the yeast's ability to ferment sugars, leading to off-flavors or incomplete fermentation. By ensuring a stable pH, brewers can consistently produce beers with the desired taste and aroma.

Oxygen management is a key consideration in batch control as well. Yeast requires oxygen for the initial stages of fermentation, but excessive oxygen can lead to off-flavors and potential contamination. Automated systems are employed to precisely control the oxygen levels in the fermentation vessel. These systems may include oxygen sensors and regulators, ensuring that the yeast receives the required amount of oxygen during the early stages while minimizing the risk of oxygen-related off-flavors.

The integration of these automated systems into the batch control process offers several advantages. Firstly, it ensures consistency in fermentation outcomes, allowing brewers to replicate successful batches with ease. Secondly, it reduces the risk of human error, as manual adjustments can be prone to variation. Additionally, automated systems can operate continuously, providing real-time monitoring and control, which is essential for maintaining the delicate balance required during fermentation. This level of control is particularly valuable in the production of specialty beers, where precise fermentation conditions are necessary to achieve unique and desirable flavors.

Craft Beer Gift Basket: A Guide to the Perfect Mix

You may want to see also

Quality assurance: Monitoring and adjusting fermentation parameters to ensure beer meets desired standards and consistency

Fed-batch beer fermentation is a process that involves gradually adding ingredients, such as sugars and yeast, to a brewing medium over time, allowing for precise control and optimization of the fermentation process. This method is particularly useful in quality assurance as it enables brewers to closely monitor and adjust various parameters to achieve consistent and high-quality beer production.

During fed-batch fermentation, the key quality assurance aspect is the ability to fine-tune the fermentation environment. This includes controlling temperature, pH levels, and oxygen levels. By maintaining optimal conditions, brewers can ensure that the yeast performs efficiently and consistently. For instance, keeping the temperature within a specific range encourages yeast activity while preventing off-flavors and aromas. Similarly, managing pH levels is crucial; too high or too low a pH can inhibit yeast function, impacting the beer's overall quality.

Oxygen management is another critical parameter. Yeast requires oxygen for fermentation, but excessive oxygen can lead to off-flavors and a decrease in beer quality. Therefore, brewers must carefully regulate oxygen levels, often by using specialized equipment that provides controlled oxygenation. This ensures that the yeast ferments the sugars efficiently without compromising the beer's taste and aroma.

Additionally, fed-batch fermentation allows for the adjustment of ingredient ratios. Brewers can precisely control the amount of sugars, yeast, and other additives, ensuring that the beer's flavor profile meets the desired standards. This level of control is essential for consistency, especially when producing different batches or variations of the same beer style.

In summary, fed-batch beer fermentation provides brewers with a powerful tool for quality assurance. By closely monitoring and adjusting temperature, pH, oxygen levels, and ingredient ratios, they can consistently produce high-quality beer. This method enables brewers to fine-tune the fermentation process, resulting in beers that meet or exceed consumer expectations in terms of taste, aroma, and overall satisfaction.

Uncover the Truth: Does Beer Add Water Weight?

You may want to see also

Frequently asked questions

Fed-batch fermentation is a process used in brewing and biotechnology where the substrate, in this case, the malt extract or sugar solution, is fed to the fermenting yeast in a controlled manner over time. This method allows for precise control of the fermentation process, ensuring optimal conditions for yeast growth and the production of desired beer flavors and characteristics.

In traditional batch fermentation, the entire substrate is added to the yeast simultaneously, and the fermentation occurs in a single step. Fed-batch fermentation, on the other hand, involves a continuous or periodic addition of substrate, which can be adjusted based on the yeast's consumption and the desired fermentation rate. This technique provides more flexibility and control over the fermentation profile.

Fed-batch fermentation offers several advantages. It allows brewers to fine-tune the fermentation process, optimizing the beer's flavor, color, and overall quality. By controlling the substrate feed rate, brewers can manage the yeast's activity, preventing over-fermentation or the production of off-flavors. This method also enables the production of beers with unique flavor profiles and the ability to experiment with different yeast strains and fermentation conditions.

Yes, the concept of fed-batch fermentation can be adapted for various alcoholic beverages beyond beer. It is commonly used in the production of wine, where controlled substrate feeding helps manage the fermentation process and the development of desired flavors. Additionally, this technique can be applied to the fermentation of spirits, such as whiskey and rum, to influence the flavor and character of the final product.