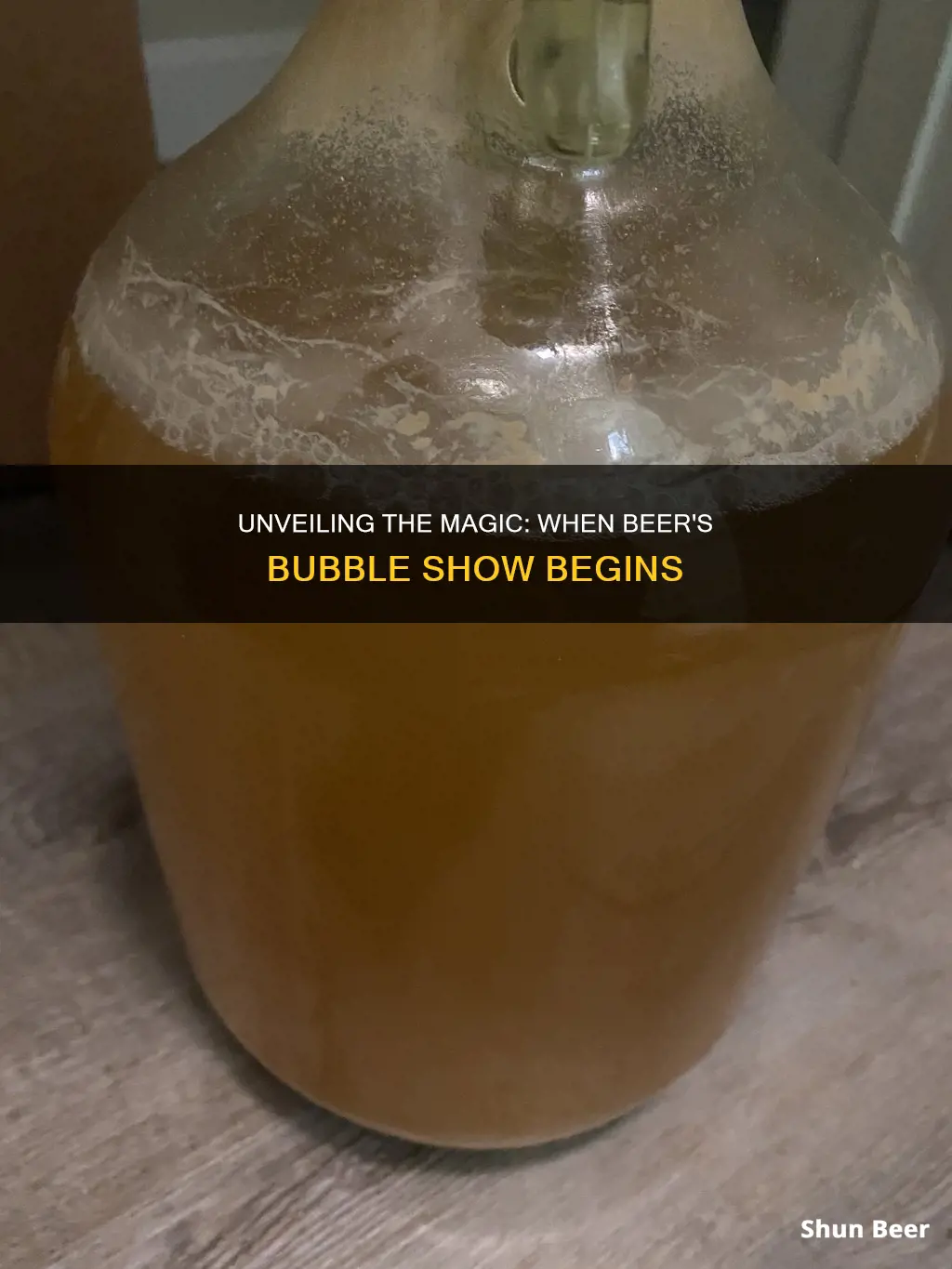

When brewing beer, the fermentation process is a crucial step where yeast transforms sugars into alcohol and carbon dioxide. One of the most exciting visual indicators of this process is the appearance of bubbles, which can be observed in the fermenting beer. These bubbles signify the release of carbon dioxide gas produced by the yeast as it metabolizes the sugars. The timing of when these bubbles become visible can vary depending on the style of beer, the yeast used, and the brewing technique employed. Typically, you'll start to see small bubbles forming on the surface of the beer within a few days to a week after pitching the yeast, but the intensity and rate of bubble formation will gradually increase over the fermentation period, which can last anywhere from one to two weeks.

What You'll Learn

- Ingredient Quality: High-quality ingredients are essential for bubble formation

- Temperature Control: Fermentation temperature affects bubble development

- Oxygen Exposure: Oxygen levels impact yeast activity and bubble creation

- Fermentation Time: Longer fermentation may lead to more bubbles

- Carbonation Level: Carbon dioxide levels determine bubble size and persistence

Ingredient Quality: High-quality ingredients are essential for bubble formation

The quality of ingredients plays a pivotal role in the bubble formation process during beer fermentation. High-quality ingredients are the cornerstone of a successful brew, ensuring that the final product not only tastes exceptional but also meets the desired level of carbonation. When it comes to beer fermentation, the ingredients you use directly impact the yeast's ability to produce carbon dioxide, which is the driving force behind those coveted bubbles.

One of the key ingredients to consider is malt. Malted grains, such as barley, provide the yeast with the necessary sugars to ferment. The quality of the malt is crucial because it determines the availability of fermentable sugars. High-quality malt will have a higher extract yield, meaning more sugars are extracted, which in turn provides more food for the yeast. This results in a more efficient fermentation process, often leading to a higher level of carbonation. Additionally, the malt's enzymes play a vital role in breaking down complex starches into simpler sugars, further enhancing the yeast's fermentation capabilities.

Hops are another essential ingredient, and their quality can significantly influence bubble formation. Hops contribute to the bitterness, flavor, and aroma of the beer, but they also play a role in the fermentation process. High-quality hops contain more essential oils and bitter acids, which can stimulate the yeast and encourage more robust bubble production. Moreover, the presence of hop oils can help stabilize the beer, preventing excessive bubbling or foaming during and after fermentation.

Water quality is often overlooked but is equally important. The mineral content and pH level of the water used in brewing can affect the yeast's performance and the overall beer quality. Soft water, for instance, may lack the necessary minerals that yeast requires for optimal fermentation. In contrast, hard water with a balanced mineral profile can provide the yeast with the necessary nutrients, promoting healthier fermentation and potentially increasing bubble formation.

In summary, investing in high-quality ingredients is a fundamental step in achieving the desired bubble formation during beer fermentation. From malt to hops and water, each ingredient contributes uniquely to the process. By selecting premium, carefully sourced materials, brewers can ensure a more consistent and satisfying level of carbonation in their beers, ultimately enhancing the overall drinking experience.

Unconventional Hair Care: A Beer-Infused Guide to Shiny Strands

You may want to see also

Temperature Control: Fermentation temperature affects bubble development

The temperature at which you start to see bubbles in beer fermentation is a critical factor in the brewing process. Fermentation temperature significantly influences the rate of bubble development and the overall quality of the beer. When yeast is introduced to the wort (the sugary liquid extracted from malted grains), it begins to metabolize the sugars, producing alcohol and carbon dioxide as byproducts. This process of fermentation is highly temperature-dependent.

In general, a warmer fermentation temperature accelerates the fermentation process, leading to faster bubble formation. This is because higher temperatures provide more energy for the yeast, increasing their metabolic activity. As a result, the yeast can consume sugars more rapidly, producing a higher volume of carbon dioxide gas. This increased gas production leads to more visible bubbles in the beer. However, it's important to note that extremely high temperatures can also have negative effects. They may cause the yeast to become less efficient, leading to a slower fermentation process and potentially off-flavors in the beer.

Conversely, a cooler fermentation temperature slows down the process, resulting in a more gradual bubble development. Lower temperatures reduce the yeast's metabolic rate, causing it to consume sugars at a slower pace. This slower fermentation can lead to a more controlled and precise flavor development, as the yeast has more time to work on the sugars, producing a cleaner and more nuanced beer. However, if the temperature is too cold, the yeast may become inactive, halting the fermentation process entirely.

The ideal fermentation temperature range for most beer styles is typically between 65°F and 75°F (18°C and 24°C). At this range, the yeast can efficiently metabolize the sugars, producing a well-balanced beer with optimal bubble formation. It's worth mentioning that different beer styles may have slightly different temperature preferences. For example, wheat beers often benefit from a slightly warmer fermentation temperature to enhance their characteristic cloudy appearance and spicy flavors.

In summary, temperature control is a crucial aspect of beer fermentation, directly impacting the rate and visibility of bubble development. Brewers can manipulate fermentation temperatures to achieve the desired bubble characteristics and overall beer quality. By understanding the relationship between temperature and fermentation, brewers can create beers with the right balance of flavors and carbonation.

Uncovering the Surprising Effects of Beer on Hair: A Scientific Exploration

You may want to see also

Oxygen Exposure: Oxygen levels impact yeast activity and bubble creation

Oxygen exposure is a critical factor in the fermentation process of beer, as it directly influences yeast activity and the subsequent bubble creation. When yeast is introduced to the beer, it begins to metabolize sugars, producing alcohol and carbon dioxide as byproducts. This process is highly sensitive to oxygen levels, which can significantly impact the fermentation outcome.

In the early stages of fermentation, when yeast is still adapting to its new environment, high oxygen levels can stimulate rapid growth and activity. This initial burst of yeast activity can lead to a rapid increase in bubble formation, often visible as small, fine bubbles rising to the surface. However, this is a transient effect, and as the yeast population stabilizes, the rate of bubble creation may slow down.

As fermentation progresses, the yeast's demand for oxygen decreases. This is because the yeast has adapted to the available oxygen levels and is now efficiently utilizing the sugars in the beer. As a result, the rate of bubble creation may become more consistent and steady, indicating a healthy and active yeast population.

Low oxygen levels, on the other hand, can lead to a different set of challenges. When oxygen is scarce, yeast may struggle to perform its metabolic functions optimally. This can result in a slower fermentation process, with fewer and larger bubbles forming. In some cases, low oxygen levels can even lead to a phenomenon known as "lag phase," where the yeast temporarily slows down or enters a dormant state, causing a temporary halt in bubble creation.

To ensure optimal fermentation, it is essential to maintain appropriate oxygen levels. This can be achieved by using oxygen-permeable fermenters or adding small amounts of oxygen to the beer during the fermentation process. By carefully managing oxygen exposure, brewers can promote healthy yeast activity and consistent bubble creation, resulting in a high-quality, well-carbonated beer.

Mastering Nitro Beer: A Guide to Pouring Perfectly Creamy Draft Beer

You may want to see also

Fermentation Time: Longer fermentation may lead to more bubbles

Fermentation is a crucial process in brewing beer, and the duration of this process can significantly impact the final product's characteristics, particularly the presence of bubbles. Longer fermentation times can indeed result in more bubbles, but understanding the science behind this phenomenon is essential for brewers to control and optimize their beer's quality.

The primary reason for increased bubble formation during extended fermentation is the continued activity of yeast. Yeast plays a vital role in fermentation by converting sugars derived from the malt into alcohol and carbon dioxide (CO2). During the initial stages of fermentation, yeast rapidly consumes the available sugars, leading to a rapid release of CO2, which forms the bubbles we observe. However, as fermentation progresses, the yeast's activity slows down, and the sugar conversion rate decreases. This reduction in yeast activity is a natural part of the fermentation process and is influenced by various factors, including temperature, yeast type, and the initial sugar concentration.

When fermentation continues for a more extended period, the yeast continues to work, albeit at a slower pace. As a result, more CO2 is produced, leading to a higher concentration of bubbles in the beer. This is particularly noticeable in styles of beer that typically undergo longer fermentation periods, such as certain Belgian ales and some wheat beers. These styles often benefit from the complexity and flavor development that longer fermentation brings, and the increased bubble formation is a desirable characteristic.

It's important to note that while longer fermentation can lead to more bubbles, it is not the sole factor determining bubble content. Other brewing techniques and ingredients also play a role. For instance, the use of dry hops or certain hop varieties can contribute to a more pronounced hop aroma, which may indirectly affect the perception of bubbles. Additionally, the type of yeast used can influence fermentation speed and bubble formation. Some yeast strains are known for their rapid fermentation, while others may take longer, resulting in different bubble characteristics.

In summary, longer fermentation times can indeed lead to more bubbles in beer due to the continued yeast activity and sugar conversion. This phenomenon is a natural part of the brewing process and contributes to the unique characteristics of different beer styles. Brewers can manipulate fermentation duration and yeast selection to achieve the desired bubble content and overall beer quality. Understanding these factors allows brewers to create beers with the right balance of flavor, aroma, and carbonation, ensuring a satisfying drinking experience for beer enthusiasts.

Understanding Alabama's Beer Limit: A Guide to Staying Within Legal Boundaries

You may want to see also

Carbonation Level: Carbon dioxide levels determine bubble size and persistence

The carbonation level in beer is a critical factor that influences the beer's overall quality and drinking experience. Carbon dioxide (CO2) is the primary gas responsible for the bubbles we see in beer, and its concentration directly affects the size and longevity of these bubbles. When brewing beer, the goal is to achieve the desired level of carbonation, which can vary depending on the style and personal preference.

The relationship between carbon dioxide levels and bubble characteristics is a fascinating aspect of beer fermentation. As the beer ferments, yeast consumes sugars and produces CO2 as a byproduct. This CO2 gradually dissolves into the beer, leading to carbonation. The amount of CO2 produced and dissolved during fermentation is directly proportional to the carbonation level. Higher CO2 concentrations result in larger bubbles, while lower levels produce smaller, more delicate bubbles.

In the early stages of fermentation, you might start noticing small bubbles forming on the surface of the beer. These bubbles are a sign that the yeast is actively working and producing CO2. As the fermentation progresses, the CO2 levels increase, leading to more prominent bubbles. The size and persistence of these bubbles depend on the specific beer style and the brewing process. For example, a light, crisp lager might have fine, small bubbles, while a Belgian ale could exhibit larger, more persistent bubbles due to higher carbonation levels.

Understanding the carbonation level is essential for brewers to create beers with the desired character. Too much CO2 can lead to a harsh, sharp sensation on the palate, while too little may result in a flat beer. Brewers often use specialized equipment to measure and control CO2 levels during fermentation, ensuring that the beer achieves the intended carbonation. This precision is particularly important in the production of craft beers, where unique and distinct flavors are sought after.

In summary, the carbonation level in beer is a result of the CO2 produced during fermentation, and it significantly impacts the beer's texture and taste. Brewers carefully manage this process to create beers with varying degrees of carbonation, catering to different preferences and styles. Whether it's a refreshing, crisp lager or a rich, fruity Belgian ale, the right carbonation level is key to delivering an exceptional drinking experience.

The Slowest Brew: Uncovering the World's Longest Fermentation Process

You may want to see also

Frequently asked questions

Bubbles, or carbonation, typically start to form in beer during the fermentation process, which usually takes around 1-2 weeks. As yeast consumes sugars and produces alcohol, it also releases carbon dioxide as a byproduct, which gets dissolved in the beer. This dissolved CO2 creates the bubbles that you might observe as a frothy head or as small bubbles rising to the surface.

The appearance of bubbles is a good indicator that fermentation is progressing, but it doesn't necessarily mean the process is complete. For an accurate assessment, you can use a hydrometer to measure the specific gravity of the beer. If the specific gravity remains stable or decreases slightly over time, it suggests that fermentation is nearing its end. Once the yeast has consumed most of the available sugars and the beer has reached a stable condition, fermentation is considered complete.

There could be several reasons for a lack of bubbles or slow bubble formation. One common issue is using an inappropriate yeast strain for the chosen beer style. Different yeasts have varying fermentation characteristics, and some may not produce enough carbonation. Additionally, if the yeast is not active or is not feeding on the sugars effectively, you might observe slow fermentation or no bubble activity. Ensuring proper yeast selection and maintaining optimal fermentation conditions are crucial to achieving the desired level of carbonation.

While adding more yeast can sometimes stimulate fermentation, it is not a guaranteed method to increase bubble formation. Yeast activity is influenced by temperature, nutrient availability, and other factors. Introducing additional yeast might provide a temporary boost, but it may also lead to other issues like off-flavors or a less clean finish. It's generally recommended to let the fermentation process unfold naturally, ensuring the yeast has sufficient time and resources to complete the process effectively.