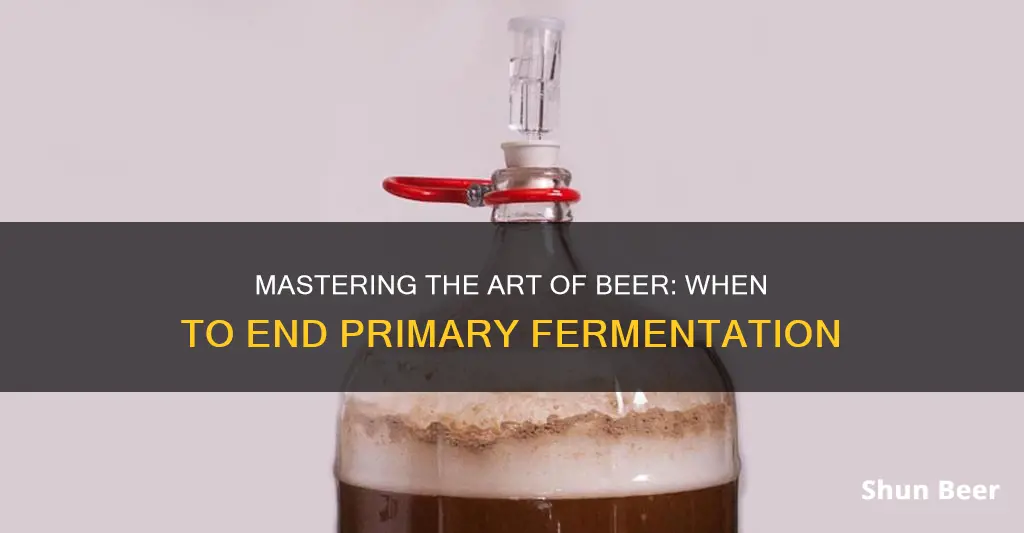

When it comes to brewing beer, primary fermentation is a crucial stage where yeast converts sugars into alcohol and carbon dioxide. However, determining when to stop this process is essential to achieving the desired flavor and character in the final product. Factors such as yeast activity, sugar consumption, and the beer's style play a significant role in deciding when to halt primary fermentation. Stopping too early may result in under-fermented beer, while extending the process beyond the optimal time can lead to off-flavors and potential spoilage. This guide will explore the key indicators and techniques to help brewers make informed decisions about when to end primary fermentation, ensuring a well-balanced and flavorful beer.

| Characteristics | Values |

|---|---|

| Temperature | Typically around 68-72°F (20-22°C) |

| Time | Usually after 1-2 weeks, but can vary based on yeast type and recipe |

| Gravity | Target OG (original gravity) is reached, indicating complete sugar conversion |

| Carbonation | Low to moderate carbonation levels are achieved |

| Flavor and Aroma | Desired flavor profile and aroma are developed |

| Clarity | Beer is clear and free from yeast and sediment |

| Yeast Activity | Yeast activity slows down, and fermentation slows to a near-complete stop |

| Alcohol Content | Desired alcohol by volume (ABV) is reached |

| pH Level | pH stabilizes and remains consistent |

| Sedimentation | Yeast and sediment begin to settle at the bottom of the fermenter |

What You'll Learn

- Temperature Control: Monitor and adjust fermentation temperature to optimize yeast activity and stop primary fermentation

- Gravity and Alcohol: Measure specific gravity and alcohol content to determine when fermentation is complete

- Carbonation and Flavor: Assess carbonation levels and flavor development to signal fermentation's end

- Yeast Activity: Observe yeast activity and signs of dormancy to halt primary fermentation

- Time and Patience: Allow sufficient time for fermentation, then stop when desired character is achieved

Temperature Control: Monitor and adjust fermentation temperature to optimize yeast activity and stop primary fermentation

Temperature control is a critical aspect of brewing beer, especially when it comes to managing the primary fermentation process. Yeast, the microorganism responsible for converting sugars into alcohol and carbon dioxide, is highly sensitive to temperature changes. Optimizing fermentation temperature is essential to ensure efficient yeast activity and a successful beer fermentation.

During primary fermentation, the yeast population rapidly increases, and their metabolic activity accelerates. This phase is crucial for achieving the desired alcohol content and flavor development in the beer. However, yeast activity is temperature-dependent. When the temperature is too low, yeast activity slows down, and fermentation becomes sluggish. Conversely, high temperatures can lead to yeast stress, causing them to become inactive or even die. Therefore, maintaining an optimal temperature range is vital.

The ideal temperature range for primary fermentation typically falls between 65°F and 75°F (18°C and 24°C). At this range, yeast activity is vigorous, and fermentation proceeds efficiently. It is essential to monitor the fermentation vessel's temperature regularly. You can use a fermentation thermometer or a temperature probe to accurately measure the temperature. Aim to keep the temperature within this optimal range throughout the fermentation process.

Adjusting the temperature can be done in several ways. One common method is to use a fermentation chamber or a temperature-controlled fermenter. These devices allow you to set and maintain a specific temperature, ensuring consistency. Another approach is to use cooling or heating jackets around the fermentation vessel. By circulating water or a heat transfer fluid, you can quickly and precisely adjust the temperature as needed. Additionally, some brewers use temperature-controlled air pumps to regulate the ambient temperature in the fermentation room.

As primary fermentation progresses, you may need to make temperature adjustments to optimize yeast activity. If the temperature drops too low, you can gently warm the fermentation vessel or add a small amount of warm water to raise the temperature. Conversely, if the temperature rises too high, you can cool the vessel or increase the ventilation to lower the ambient temperature. Regular monitoring and adjustments will help you fine-tune the fermentation process and ensure a successful beer.

The Ultimate Guide to Beer Cheese Soup: Potatoes or No?

You may want to see also

Gravity and Alcohol: Measure specific gravity and alcohol content to determine when fermentation is complete

The process of primary fermentation in beer brewing is a crucial stage where the transformation of sugars into alcohol and carbon dioxide occurs. To ensure the beer's quality and character, it's essential to know when this fermentation process is complete. One of the most reliable methods to achieve this is by monitoring the specific gravity and alcohol content of the beer.

Specific gravity, often referred to as 'original gravity' (OG) and 'final gravity' (FG), is a measure of the density of the beer. It is typically expressed as a percentage and indicates the amount of solids (such as sugars and proteins) present in the liquid. During fermentation, as yeast consumes sugars, the specific gravity of the beer gradually decreases. When the fermentation is nearly complete, the specific gravity will stabilize, and further changes will be minimal. This stabilization is a clear indicator that the yeast has finished converting the available sugars into alcohol and carbon dioxide.

Measuring the specific gravity can be done using a hydrometer, a simple and affordable tool for homebrewers. The hydrometer is placed in the fermenter, and the reading is taken. The specific gravity should be recorded at the beginning of the fermentation process (OG) and then periodically until it stabilizes (FG). A typical range for primary fermentation in beer is between 1.040 and 1.070 for OG, and the FG should be significantly lower, often around 1.010 or lower, depending on the style of beer.

Alcohol content, or 'ABV' (alcohol by volume), is another critical parameter to consider. As fermentation progresses, the alcohol content increases. When the yeast has consumed most of the available sugars, the alcohol level will stabilize, and further increases will be minimal. This stabilization in alcohol content is a strong sign that primary fermentation is complete. A typical beer fermentation may result in an alcohol content ranging from 3% to 8% ABV, but this can vary widely depending on the style and recipe.

By regularly measuring the specific gravity and alcohol content, you can accurately determine when to stop the primary fermentation process. This ensures that the beer is not over-fermented, which could lead to off-flavors or a lack of desired characteristics. Additionally, stopping fermentation at the right time allows for the beer to condition and mature, developing the flavors and aromas that make it enjoyable. It's a delicate balance, but with consistent measurements, you can master the art of brewing and produce exceptional beers.

Crafting a Beer Cap Map: A Guide to Organizing Your Collection

You may want to see also

Carbonation and Flavor: Assess carbonation levels and flavor development to signal fermentation's end

The primary fermentation of beer is a crucial stage in the brewing process, where the majority of the alcohol and carbon dioxide are produced. It is essential to monitor and control this process to ensure the desired flavor and carbonation levels are achieved. One of the key indicators of when to stop primary fermentation is the measurement of carbonation and flavor development.

Carbonation is a critical aspect of beer quality, as it contributes to the overall taste and mouthfeel. During primary fermentation, yeast converts sugars into alcohol and carbon dioxide. The carbon dioxide produced is dissolved in the beer, creating carbonation. Brewers aim for a specific level of carbonation, which can vary depending on the beer style. For example, a light lager may have a lower carbonation level compared to a sparkling ale. As fermentation progresses, the carbonation level increases, and it is essential to stop the process when the desired carbonation is reached.

Assessing carbonation can be done through various methods. One common technique is the use of a hydrometer, which measures the specific gravity of the beer. As fermentation progresses, the specific gravity should gradually decrease due to the consumption of sugars and the production of alcohol. When the specific gravity stabilizes and remains consistent over several days, it indicates that the majority of sugar has been fermented, and the carbonation level is at the desired point. Additionally, brewers can perform a carbonation test by releasing a small amount of beer into a carbonation bottle and measuring the time it takes for the bubbles to dissipate.

Flavor development is another critical factor in determining the end of primary fermentation. The yeast's activity influences the beer's flavor profile. During fermentation, the yeast consumes sugars and produces various compounds, including esters, aldehydes, and acids, which contribute to the beer's aroma and taste. Brewers aim for a balanced flavor profile, ensuring that the beer is not overly sweet or acidic. As fermentation progresses, the beer's flavor should become more pronounced and stable. When the desired flavor complexity and balance are achieved, and no significant changes are observed over a few days, it is a good indicator that primary fermentation is complete.

It is important to note that stopping primary fermentation is an art and a science. Brewers often rely on their experience and sensory analysis to make these decisions. They may also use advanced brewing software that provides real-time data on fermentation progress, including carbonation and flavor development. By carefully monitoring these parameters, brewers can ensure that the beer is fermented to perfection, resulting in a high-quality product with the desired carbonation and flavor characteristics.

Unraveling Beer's Magic: The Three Fermentation Phases Explained

You may want to see also

Yeast Activity: Observe yeast activity and signs of dormancy to halt primary fermentation

Understanding yeast activity is crucial for successful beer fermentation. Yeast, the microscopic organisms responsible for converting sugars into alcohol and carbon dioxide, play a pivotal role in the brewing process. However, their activity is not constant; it fluctuates, and knowing when to stop the primary fermentation is an art that every brewer aims to master.

The primary fermentation stage is where yeast consumes the sugars present in the wort (the sugary liquid extracted from malted grains) and produces alcohol and carbon dioxide. This process typically occurs at a controlled temperature, usually around 65-75°F (18-24°C). The yeast's activity can be observed through several indicators. Firstly, the specific gravity of the wort should decrease as the yeast consumes the sugars. This can be measured using a hydrometer, and a consistent drop in specific gravity over time indicates active fermentation. Additionally, the release of carbon dioxide can be monitored; as the yeast becomes more active, the rate of CO2 production increases.

However, yeast activity is not a continuous process. It undergoes phases of activity and dormancy. During dormancy, yeast cells become less active and may even die off, especially if the fermentation conditions are not optimal. This dormancy can be triggered by various factors, including temperature, nutrient depletion, or the presence of inhibitors. For instance, if the fermentation temperature is too high, yeast activity may slow down or stop, leading to a stuck fermentation. Similarly, if the yeast runs out of nutrients, it will enter a dormant state, halting the fermentation process.

To halt primary fermentation, one must carefully observe the signs of yeast dormancy. When the yeast becomes inactive, the fermentation slows down, and the specific gravity readings stop decreasing. The rate of CO2 production decreases, and the beer may start to clear, indicating that the yeast has finished its work. At this point, it is essential to stop the fermentation to prevent over-fermentation, which can lead to off-flavors and a harsh taste.

Brewers often use a combination of techniques to manage yeast activity. This includes adjusting the fermentation temperature, adding nutrients or yeast food to stimulate activity, or even using different yeast strains with varying fermentation characteristics. By closely monitoring yeast activity and understanding the signs of dormancy, brewers can precisely control the fermentation process, ensuring a high-quality beer with the desired flavor profile.

Exploring the Capacity: Sizing Up Commercial Beer Fermenters

You may want to see also

Time and Patience: Allow sufficient time for fermentation, then stop when desired character is achieved

The art of brewing beer is a delicate balance of science and creativity, and one of the most critical aspects is knowing when to halt the primary fermentation process. This stage is where the magic happens, transforming simple ingredients into a complex beverage with unique flavors and aromas. However, it requires patience and a keen eye to ensure the beer reaches its full potential.

Primary fermentation is a dynamic process where yeast consumes sugars and produces alcohol and carbon dioxide. The duration of this phase can vary significantly depending on the beer style, yeast type, and desired outcome. For instance, a robust, dark ale might require an extended fermentation period to develop its rich, malty flavors, while a crisp, light lager could ferment more quickly, leaving a cleaner taste profile. As a general rule, the longer the fermentation, the more complex the beer's flavor tends to be, but there are exceptions, and it's essential to trust your palate.

Stopping primary fermentation at the right time is an art that brewers hone over years of experience. It involves monitoring the beer's progress and making adjustments as necessary. One common method is to measure the specific gravity of the beer, which indicates the concentration of sugars. As fermentation progresses, the specific gravity should steadily decrease. When it stabilizes, often at a lower level than the starting point, it's a strong indicator that fermentation is complete. However, this is not an exact science, and other signs can guide your decision.

Another approach is to taste the beer regularly. As fermentation nears its end, the beer's flavor should become more balanced and well-rounded. The harsh, green apple-like flavors produced by yeast should fade, and the beer should exhibit the character you envisioned. This method requires a highly developed palate and a good understanding of the beer's style, but it can be a rewarding way to brew.

In summary, stopping primary fermentation is a delicate balance of timing and taste. It requires patience, regular monitoring, and a keen sense of when the beer has reached its desired character. Whether you're a seasoned brewer or a novice, allowing sufficient time for fermentation and then making the call to halt the process is a crucial step in crafting exceptional beer.

Unraveling the Fermentable Nature of Beer: Carbohydrates and Beyond

You may want to see also

Frequently asked questions

Primary fermentation is typically considered complete when the beer has reached a stable gravity reading and there is no significant activity in the yeast. You can monitor the gravity of the beer using a hydrometer, and a stable reading indicates that the yeast has consumed most of the available sugars. Additionally, you may observe a decrease in the yeast's activity, such as reduced bubbling or no visible yeast movement.

Continuing primary fermentation beyond the optimal time can lead to several issues. The beer may become overly carbonated, resulting in a sharp, unpleasant taste. Over-fermentation can also cause off-flavors and aromas, such as esters or sulfur compounds. Furthermore, prolonged fermentation may lead to a loss of desired flavors and aromas, as the yeast may start to produce unwanted byproducts.

Yes, there are a few signs to look out for when determining if the yeast is exhausted. One sign is a significant drop in gravity, indicating that the yeast has consumed all available sugars. Another indicator is a lack of visible yeast activity, where the yeast no longer bubbles or moves around in the fermenter. Additionally, the beer may start to develop a cloudy appearance, suggesting that the yeast has settled and is no longer active.

Stopping primary fermentation early is generally not recommended, as it may result in a beer that is not fully fermented and lacks the desired flavor and character. However, if you have a specific reason to halt fermentation early, such as a brewing emergency, you can transfer the beer to a conditioning vessel and continue the process there. This will allow the beer to mature and develop flavors without further yeast activity.

Several factors can affect the duration of primary fermentation. The type of yeast used plays a significant role, as different yeast strains have varying fermentation times. The original gravity of the wort, the temperature of the fermentation vessel, and the yeast's food source (available sugars) also influence the fermentation process. Higher gravity worts and warmer temperatures generally speed up fermentation, while cooler temperatures and lower gravity can slow it down.