Fermentation is a crucial process in beer-making, but it can also generate heat. This heat is a byproduct of the yeast's metabolic activities, which convert sugars into alcohol and carbon dioxide. The temperature increase during fermentation can range from a few degrees to as much as 100°F (38°C), depending on the yeast strain and fermentation conditions. Understanding this heat generation is essential for brewers to control the fermentation process and ensure the beer's quality and consistency.

| Characteristics | Values |

|---|---|

| Process | Fermentation is a metabolic process where sugars are converted into alcohol and carbon dioxide by yeast. |

| Heat Generation | While fermentation does not directly create heat, it can influence the temperature of the beer. The process can generate a small amount of heat, but this is typically minimal and not noticeable. |

| Temperature Control | Brewers often control the fermentation temperature to influence the beer's flavor, aroma, and overall character. Warmer temperatures can lead to more estery and fruity notes, while cooler temperatures may result in a cleaner, crisper profile. |

| Alcohol Content | The alcohol content in beer is a result of fermentation, not a direct heat-producing process. Higher alcohol beers may have a slightly warmer sensation due to the alcohol's effect on body temperature. |

| Secondary Fermentation | Some beers undergo a secondary fermentation, which can further refine the beer's character and may slightly impact temperature. |

| Environmental Factors | External factors like room temperature and the insulation of the fermentation vessel can also affect the beer's temperature during fermentation. |

What You'll Learn

- Fermentation Process: Yeast converts sugars into alcohol and carbon dioxide, generating heat

- Enzyme Activity: Enzymes break down maltose, releasing energy as heat

- Fermentation Temperature: Higher temperatures increase fermentation rate and heat production

- Yeast Metabolism: Yeast respiration produces heat as a byproduct

- Fermentation Duration: Longer fermentation times can lead to more heat accumulation

Fermentation Process: Yeast converts sugars into alcohol and carbon dioxide, generating heat

The fermentation process in beer production is a fascinating and intricate procedure that involves the transformation of sugars into alcohol and carbon dioxide. At the heart of this process is the yeast, a microscopic organism that plays a pivotal role in the beer's flavor, aroma, and overall character. One intriguing aspect of fermentation is the heat it generates, which is often overlooked but holds significant importance in the brewing process.

When yeast ferments sugars, it undergoes a series of biochemical reactions. In simple terms, yeast acts as a catalyst, breaking down complex sugars, primarily maltose, into simpler molecules. This process is highly exothermic, meaning it releases energy in the form of heat. The heat generation is a natural byproduct of the yeast's metabolic activities and is an essential factor in the fermentation process. As the yeast consumes sugars, it produces alcohol and carbon dioxide, and this reaction is accompanied by a noticeable increase in temperature.

The temperature rise during fermentation is not just a random occurrence but is carefully monitored and controlled by brewers. Yeast fermentation temperature is a critical parameter in brewing, as it directly influences the flavor development and the overall quality of the beer. Warmer temperatures can lead to faster fermentation, which might be desirable in some cases, but it can also result in a loss of subtler flavors and aromas. Conversely, cooler temperatures may slow down fermentation, allowing for more nuanced flavor development.

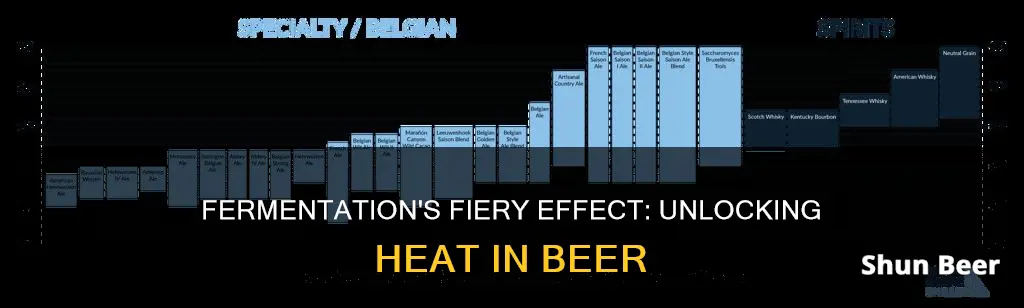

Brewers often use this heat generation to their advantage. By controlling the fermentation temperature, they can manipulate the beer's characteristics. For instance, a higher fermentation temperature might enhance the beer's fruity or estery notes, while a cooler temperature could bring out more malt-forward flavors. This technique is particularly useful in styles like wheat beers or certain Belgian ales, where a warmer fermentation profile is desired.

In summary, the fermentation process in beer is a complex interplay of yeast, sugars, and various environmental factors, including temperature. The heat generated during fermentation is a natural and integral part of this process, offering brewers a tool to craft beers with unique and desirable characteristics. Understanding this heat generation and its impact allows brewers to fine-tune their recipes and create beers that cater to a wide range of tastes and preferences.

The Secret to Modelo's Refreshing Twist: Lime's Role

You may want to see also

Enzyme Activity: Enzymes break down maltose, releasing energy as heat

The process of fermentation in beer is a fascinating interplay of biology and chemistry, and one of the key aspects is the role of enzymes in breaking down maltose, a crucial step in the brewing process. Enzymes are biological catalysts that speed up chemical reactions without being consumed in the process. In the context of beer fermentation, the enzyme amylase is primarily responsible for the breakdown of maltose, a disaccharide derived from starch.

When malted grains are crushed and soaked in water, they release starches that are then converted into maltose through a process called saccharification. This is where enzyme activity comes into play. Amylase enzymes, produced by various sources like yeast and bacteria, catalyze the hydrolysis of maltose into glucose and smaller oligosaccharides. This enzymatic reaction is highly efficient, ensuring that the maltose is rapidly broken down into simpler sugars. The breakdown of maltose is essential because it provides the yeast with the necessary energy source for fermentation.

As the enzymes work their magic, a fascinating phenomenon occurs. The hydrolysis of maltose releases energy in the form of heat. This might seem counterintuitive, as one would expect an exothermic reaction to release heat. However, the energy released during this process is a result of the enzymes lowering the activation energy required for the reaction to proceed. This means that the reaction can occur more rapidly and efficiently, generating a small amount of heat as a byproduct. This heat generation is a natural consequence of the enzymatic process and is an important consideration in brewing, especially when maintaining precise temperature control during fermentation.

The release of heat during enzyme activity has implications for the brewing process. Brewers often use temperature control to regulate enzyme activity, ensuring that the maltose is broken down at the optimal rate. If the temperature is too low, enzyme activity may be insufficient, leading to incomplete maltose breakdown. Conversely, higher temperatures can activate more enzymes, potentially causing over-fermentation or the production of unwanted byproducts. Therefore, maintaining the right temperature range is crucial to achieving the desired beer flavor and quality.

In summary, the fermentation process in beer production involves enzymes breaking down maltose, a critical step in sugar conversion. This enzymatic activity releases energy as heat, which is a natural byproduct of the reaction. Understanding and managing enzyme activity through temperature control are essential skills for brewers to craft the perfect beer, ensuring a harmonious balance of flavors and a smooth fermentation process. This intricate dance of chemistry and biology is what makes the art of brewing so captivating.

The Perfect Pickled Beer: A Tasty Experiment

You may want to see also

Fermentation Temperature: Higher temperatures increase fermentation rate and heat production

The process of fermentation in beer is a fascinating and intricate art, and one of the key factors that brewers often consider is temperature. While it might seem counterintuitive, higher temperatures can actually enhance the fermentation process and contribute to the overall quality of the beer. This phenomenon is primarily attributed to the increased rate of enzymatic reactions and the subsequent heat production.

When yeast is introduced to the beer, it initiates the fermentation process by breaking down sugars present in the wort. This breakdown is facilitated by enzymes, which catalyze the conversion of complex carbohydrates into simpler sugars, such as ethanol and carbon dioxide. Interestingly, these enzymatic reactions are temperature-dependent. As the temperature rises, the rate of these reactions accelerates, leading to a faster fermentation process. This is because higher temperatures provide more energy to the enzymes, allowing them to function at an optimal pace.

The increased fermentation rate with higher temperatures is advantageous for several reasons. Firstly, it reduces the overall fermentation time, which is crucial for brewers as it allows for quicker production cycles. Secondly, a faster fermentation can result in a more robust flavor development, as the beer is exposed to the yeast's activity for a shorter duration. This can lead to a more complex and well-rounded beer profile. However, it's important to note that there is an optimal temperature range for fermentation, typically between 65°F and 75°F (18°C and 24°C), as temperatures that are too high can lead to off-flavors and potential yeast death.

The heat produced during fermentation is another fascinating aspect of this process. As the yeast metabolizes sugars, it generates heat as a byproduct. This heat can contribute to the overall temperature of the fermentation vessel, which is carefully monitored by brewers. While this heat may seem like a challenge, it can actually help maintain a consistent temperature, especially in larger brewing systems. Additionally, the heat can contribute to the overall character of the beer, as it can influence the flavor and aroma compounds produced during fermentation.

In summary, higher temperatures during fermentation can significantly impact the beer-making process. They increase the fermentation rate, allowing brewers to achieve their desired beer styles in a shorter time. Moreover, the heat generated during this process can be harnessed to maintain optimal temperatures and contribute to the unique characteristics of the final product. Understanding and controlling fermentation temperature is an art that brewers master to create exceptional beers.

Elevate Your Steak Game: A Guide to Beer Marinades

You may want to see also

Yeast Metabolism: Yeast respiration produces heat as a byproduct

Yeast metabolism is a fascinating process that plays a crucial role in the fermentation of beer. When yeast undergoes respiration, it generates heat as a byproduct, which is an essential aspect of the brewing process. This heat production is a result of the yeast's metabolic activities and is closely tied to the fermentation process itself.

During fermentation, yeast cells break down sugars, primarily glucose, to produce ethanol and carbon dioxide. This metabolic pathway is known as alcoholic fermentation or ethanol fermentation. As the yeast cells metabolize the sugars, they go through a series of biochemical reactions, and this process is highly efficient in energy production. The energy released during these reactions is initially stored in the form of adenosine triphosphate (ATP), the primary energy currency of cells.

The ATP generated during fermentation is then utilized by the yeast for various cellular processes, including the synthesis of new cellular components and the maintenance of cellular functions. However, a significant portion of this energy is also released as heat. This heat production is a natural consequence of the yeast's metabolic activities and is essential for the overall fermentation process. The heat helps to maintain the optimal temperature range for yeast growth and activity, ensuring efficient fermentation.

The heat generated by yeast respiration has a direct impact on the brewing process. Brewers carefully monitor the temperature of the fermentation vessel to control the rate and efficiency of fermentation. The heat produced by yeast activity can be harnessed to create a controlled environment, allowing brewers to manage the fermentation process effectively. This temperature control is crucial, as it influences the flavor, aroma, and overall quality of the beer.

Additionally, the heat generated during yeast respiration contributes to the development of the beer's character. The temperature variations during fermentation can affect the beer's flavor profile, body, and mouthfeel. Brewers often use this heat-related process to their advantage, creating unique and desirable beer styles. Understanding the relationship between yeast metabolism, heat production, and fermentation is essential for brewers to craft high-quality beers with consistent and desirable characteristics.

The Art of Rim Decor: Enhancing Your Pumpkin Beer Experience

You may want to see also

Fermentation Duration: Longer fermentation times can lead to more heat accumulation

Fermentation is a crucial process in beer-making, and it's an intriguing phenomenon that can generate heat. While the primary goal of fermentation is to convert sugars into alcohol and carbon dioxide, it's important to understand that this process is not without its side effects, especially in terms of temperature control. One significant factor that influences the heat generated during fermentation is the duration of the process.

When yeast ferments wort (the sugary liquid extracted from malted grains), it undergoes a series of biochemical reactions. These reactions are highly efficient at converting sugars, but they also produce a considerable amount of heat as a byproduct. Longer fermentation times provide more opportunities for these reactions to occur, resulting in a higher cumulative heat output. This is particularly noticeable in the early stages of fermentation when the yeast is most active. As the yeast population increases, so does the rate of fermentation, and consequently, the heat generated.

The accumulation of heat during extended fermentation periods can have both positive and negative impacts. On the positive side, higher temperatures can enhance the flavor development of the beer, leading to more complex and desirable taste profiles. Certain yeast strains and beer styles thrive in warmer conditions, allowing for unique flavor characteristics. However, excessive heat can also negatively affect the beer's quality. It may lead to off-flavors, such as a 'cooked' or 'flabby' taste, and can even cause the yeast to die or become inactive, halting the fermentation process.

To manage this heat accumulation, brewers employ various techniques. One common method is to use a technique called 'temperature control' or 'temperature management'. This involves monitoring and adjusting the fermentation temperature to maintain an optimal range. By keeping the temperature stable, brewers can ensure that the yeast works efficiently without overheating, thus preventing the negative effects of excessive heat. Additionally, some brewers may use specific yeast strains that are more heat-tolerant, allowing for longer fermentation times without compromising the beer's quality.

In summary, longer fermentation times can indeed lead to more heat accumulation during the beer-making process. While this can have some positive effects on flavor development, it also requires careful management to avoid negative consequences. Brewers have developed techniques to control temperature and select appropriate yeast strains to optimize the fermentation process and produce high-quality beers. Understanding the relationship between fermentation duration and heat generation is essential for achieving consistent and desirable beer results.

Fishy Fermentation: Uncovering the Truth Behind American Craft Beer's Unique Ingredient

You may want to see also

Frequently asked questions

Yes, fermentation does produce heat as a byproduct. The process involves yeast metabolizing sugars and converting them into alcohol and carbon dioxide. This metabolic activity releases energy, which is then dissipated as heat, causing the fermentation vessel to warm up.

The amount of heat generated can vary depending on several factors, including the specific beer style, yeast strain, fermentation temperature, and duration. Generally, the heat production is more significant in higher-gravity beers and when using ale yeasts at warmer temperatures. For instance, a typical ale fermentation might increase the temperature by 2-5°C (3.6-9°F) over a few days.

In most cases, the heat produced during fermentation is not a significant issue for beer quality. However, excessive heat can lead to off-flavors and aromas, especially in the case of high-temperature fermentations. Brewers often monitor and control fermentation temperatures to ensure the desired flavor profile and prevent any negative impacts on the beer's character.

Absolutely! Brewers employ various techniques to manage fermentation temperature. These include using fermentation chambers or jackets to control the environment, adding cooling coils to the fermentation vessel, or even using yeast strains specifically adapted to higher temperatures. Proper temperature control is crucial for achieving consistent and high-quality beer.