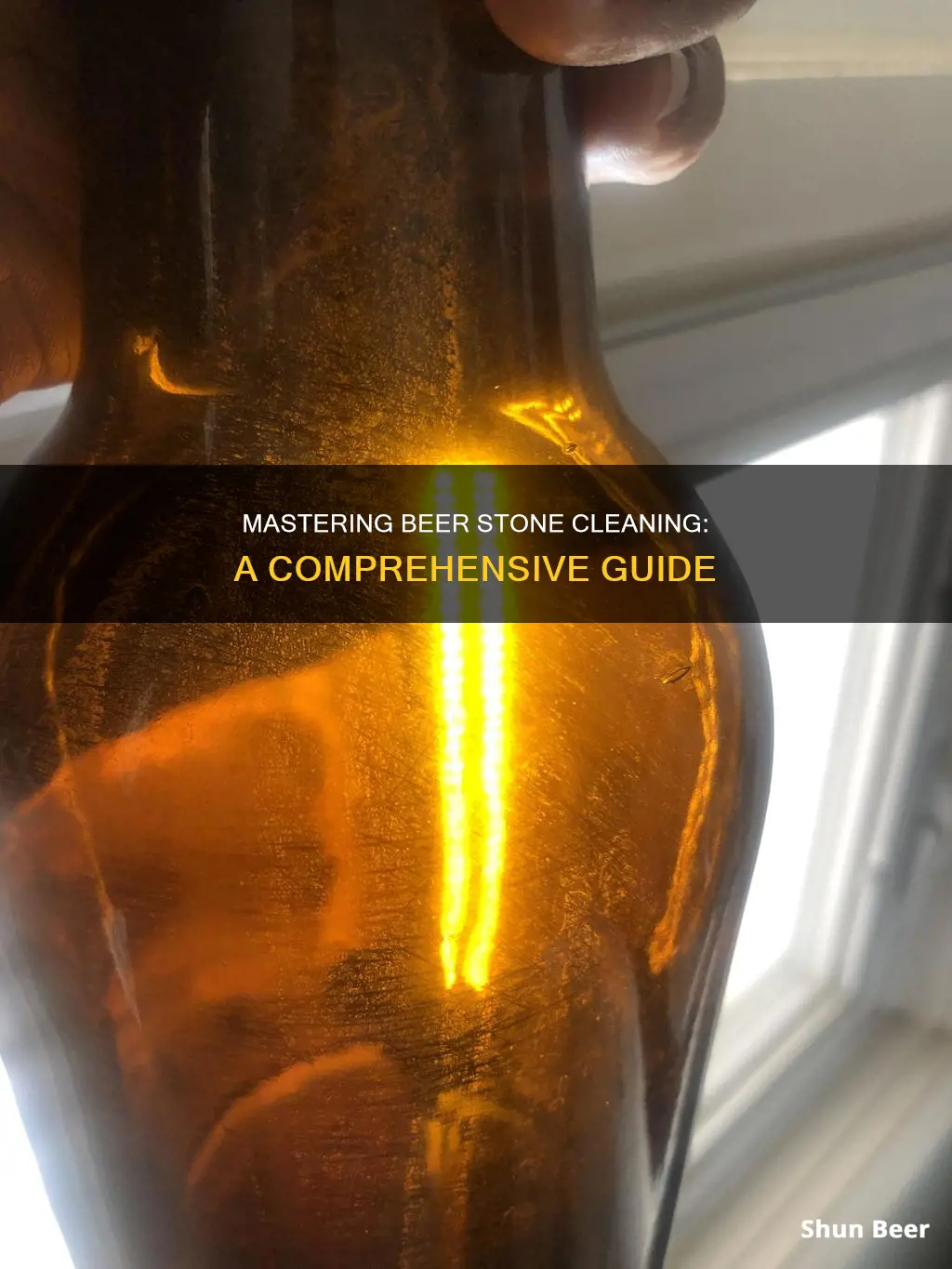

Beer stone, also known as beer sediment or beer scum, is a common issue for homebrewers and beer enthusiasts. It forms in the fermentation vessel and can affect the taste and clarity of the beer. Cleaning beer stone is essential to maintain the quality of your brews and ensure a consistent fermentation process. This guide will provide a step-by-step approach to effectively remove beer stone, covering various methods and tools to help you keep your brewing equipment in top condition.

What You'll Learn

- Identify Stone: Recognize beer stone buildup on taps and lines

- Disassemble System: Carefully remove parts for cleaning

- Use Acidic Cleaner: Employ citric acid or similar for effective removal

- Scrub and Rinse: Aggressively clean and thoroughly rinse

- Sanitize and Reassemble: Ensure proper sanitation before reinstalling

Identify Stone: Recognize beer stone buildup on taps and lines

Beer stone, also known as beer scale or beer deposits, is a common issue in the brewing industry and can be a nuisance for any beer enthusiast. It occurs when minerals in the water used for brewing react with the hops and other ingredients, forming a hard, mineral-rich deposit inside the brewing equipment, taps, and lines. This buildup can lead to off-flavors, reduced beer quality, and even equipment malfunction. Therefore, it's crucial to identify and address beer stone buildup promptly.

The first step in tackling beer stone is to recognize its presence. Beer stone can accumulate in various parts of the brewing system, including faucets, pipes, kettles, and even the tap handle itself. One of the most noticeable signs of beer stone buildup is a change in the taste of the beer. If the beer starts to taste 'funky' or 'off', it could be an indication of mineral deposits affecting the flavor. Additionally, you might notice a slight cloudiness or haze in the beer, especially if the stone buildup is significant.

Another way to identify beer stone is by visually inspecting the brewing equipment. Over time, you may notice a white, chalky residue or a layer of mineral deposits on the interior walls of the taps, lines, and kettles. This buildup often appears as a hard, shiny layer that can be scraped off, revealing the underlying metal or glass. Beer stone can also cause a decrease in water flow, making it noticeable when you turn on a tap, as the water may come out slowly or with a reduced flow rate.

To confirm the presence of beer stone, you can perform a simple test. Fill a glass with hot water and run it under the tap, allowing the water to cool slightly. If you notice a white, cloudy film forming on the surface of the water, it could be an indication of beer stone. This test is particularly useful for identifying buildup in the tap lines and faucets. Regularly checking for these signs can help you stay ahead of the problem and prevent extensive buildup.

Once you've identified beer stone buildup, it's essential to take immediate action to clean and maintain your brewing equipment. This may involve using specialized cleaning agents designed for beer stone removal, such as those containing citric acid or other food-grade acids. Proper cleaning techniques and regular maintenance can help prevent future occurrences and ensure the longevity of your brewing setup.

Coopers DIY Lager: A Craft Beer Clone?

You may want to see also

Disassemble System: Carefully remove parts for cleaning

When it comes to tackling beer stone, a meticulous disassembly of your brewing system is the first crucial step. This process ensures that you can effectively clean and maintain each component, preventing the buildup of mineral deposits and maintaining the quality of your brews. Here's a comprehensive guide on how to carefully remove parts for a thorough cleaning:

Step 1: Identify the Components

Start by familiarizing yourself with the various parts of your brewing setup. This includes the kettle, fermenter, pipes, taps, and any additional accessories like chillers or carbonators. Understanding the layout and function of each component is essential before you begin disassembly.

Step 2: Gather the Right Tools

Disassembling a brewing system requires the right tools to ensure a thorough and safe process. You'll need screwdrivers of various sizes, Allen keys, wrenches, and possibly a specialized tool kit designed for homebrewing. Having the appropriate tools will make the disassembly process smoother and less prone to damage.

Step 3: Turn Off Power and Release Pressure

Before you begin, ensure that your brewing system is powered off and disconnected from any power sources. If your system uses gas or electric elements, turn them off and allow them to cool down. Additionally, release any built-up pressure from the lines to prevent accidents during disassembly.

Step 4: Remove Accessible Parts

Begin by removing easily accessible parts such as faucets, taps, and any removable components. These parts are often designed to come off without requiring extensive tools. Carefully unscrew or unclamp these parts, setting them aside in a clean, dry area.

Step 5: Disassemble Pipes and Hoses

Next, focus on the pipes and hoses that connect various components. Use the appropriate wrenches or pliers to carefully disconnect these fittings. Take note of the orientation of each fitting to ensure proper reassembly later. Soak any removable pipes in a cleaning solution to loosen any built-up stone or deposits.

Step 6: Take Apart the Main Components

For the main brewing components like the kettle and fermenter, you may need to disassemble them further. This might involve removing strainers, filters, or other internal parts. Use your tools to carefully pry or unscrew these parts, being mindful of any delicate components that could be damaged during the process.

Remember, the key to successful beer stone cleaning is patience and attention to detail. Take your time, follow these steps carefully, and you'll be well on your way to a thoroughly cleaned brewing system.

The Ultimate Guide to Cleaning Your Beer Growler: Tips and Tricks

You may want to see also

Use Acidic Cleaner: Employ citric acid or similar for effective removal

If you're dealing with beer stone buildup, an acidic cleaner can be a powerful tool to remove it effectively. Citric acid, in particular, is a popular choice for this purpose due to its ability to dissolve mineral deposits and break down the calcium carbonate that forms beer stone. Here's a step-by-step guide on how to use an acidic cleaner to tackle this issue:

Preparation: Start by gathering the necessary supplies. You'll need citric acid crystals or powder, a large pot or basin, a heat-safe container for mixing, and a stirring tool. Citric acid is available at most grocery or health food stores, often used for making homemade lemonade or as a dietary supplement.

Mixing the Cleaner: In your heat-safe container, combine the citric acid with an equal amount of water. For example, if you use 1/2 cup of citric acid, add 1/2 cup of water. Stir the mixture until the acid is fully dissolved. The resulting solution will be a pale yellow or clear liquid.

Application: Pour the citric acid solution into your pot or basin. Immerse the beer stone in this acidic bath, ensuring it is fully covered. Allow the stone to soak for a period of time, typically around 30 minutes to an hour. The acid will start to dissolve the beer stone, making it softer and easier to remove.

Scraping and Rinsing: After the soaking period, use a non-abrasive tool like a plastic scraper or a soft-bristled brush to gently scrape away the softened beer stone. Work carefully to avoid scratching the surface of your brewing equipment. Once you've removed as much as possible, rinse the area thoroughly with warm water to neutralize the acid and prevent any residue from affecting the taste of your beer.

Regular Maintenance: To prevent beer stone buildup, consider using an acidic cleaner regularly as part of your brewing maintenance routine. This proactive approach will help keep your brewing equipment in optimal condition and ensure the quality of your beer remains consistent. Remember to always follow safety guidelines when handling chemicals, and wear protective gear if necessary.

The Beer Bag Conundrum: Uncovering the Mystery

You may want to see also

Scrub and Rinse: Aggressively clean and thoroughly rinse

When it comes to tackling beer stone, a thorough scrub and rinse are essential steps in the cleaning process. Beer stone, often referred to as 'beer gunk' or 'beer scum,' can accumulate in various parts of your brewing equipment, including kettles, fermenters, and pipes. This buildup not only affects the taste of your beer but can also lead to off-flavors and reduced efficiency in your brewing process. Here's a detailed guide on how to effectively scrub and rinse your brewing equipment to remove beer stone.

Scrubbing: Start by disassembling your brewing equipment into its individual components, such as kettles, fermenters, and pipes. Beer stone often forms in these areas due to the constant contact with hot water and beer. Use a stiff-bristled brush or a specialized beer stone brush to scrub each surface vigorously. Focus on areas where stone is most likely to accumulate, such as the interior walls of the kettle, the bottom of the fermenter, and the joints of pipes. Apply moderate to heavy pressure while brushing to ensure you're removing as much stone as possible. For stubborn deposits, consider using a metal scraper or a specialized beer stone removal tool, being careful not to scratch the surface of your equipment.

Rinsing: After scrubbing, it's crucial to rinse your equipment thoroughly to remove any loose particles and residue. Fill your brewing equipment with hot water, ensuring it's at a temperature that's comfortable to handle. Let the water sit for a few minutes to allow it to dissolve any remaining beer stone. Then, drain the water and rinse the equipment with a steady stream of hot water. For a more thorough rinse, consider using a garden hose or a pressure washer, especially for larger brewing setups. Make sure to direct the water flow to all areas that were previously scrubbed to ensure no stone particles remain.

Final Rinse: To ensure the highest level of cleanliness, perform a final rinse using cold water. Cold water helps to solidify any remaining beer stone, making it easier to remove. This step is particularly important for glassware and equipment that will come into direct contact with the beer during the brewing process. Use a soft cloth or sponge to wipe down the interior surfaces, ensuring no stone or residue is left behind.

By following these scrubbing and rinsing techniques, you can effectively remove beer stone from your brewing equipment, ensuring cleaner, better-tasting beer and optimizing the performance of your brewing setup. Remember, regular cleaning and maintenance are key to successful homebrewing.

Mastering the Art of Beer Fermenter Cleaning: A Comprehensive Guide

You may want to see also

Sanitize and Reassemble: Ensure proper sanitation before reinstalling

Sanitizing and reassembling your beer stone after cleaning is an essential step to ensure the longevity of your brewing equipment and the quality of your beer. Proper sanitation prevents the growth of bacteria, yeast, and other microorganisms that can negatively impact the flavor and safety of your beverage. Here's a step-by-step guide to help you through this process:

Disassemble with Care: Begin by carefully disassembling the beer stone. This usually involves removing any removable parts such as filters, strainers, or hop bags. Take note of the specific design and layout of your stone to ensure you reassemble it correctly.

Rinse Thoroughly: Start the sanitization process by rinsing the stone with hot water. This initial rinse helps to remove any loose debris and prepares the surface for more intensive cleaning. Use a gentle stream of water to avoid pushing dirt further into the stone's crevices.

Sanitize with Chemicals: For effective sanitization, use a chemical disinfectant specifically designed for brewing equipment. Common choices include iodine solutions, quaternary ammonium compounds (QUATS), or hydrogen peroxide-based sanitizers. Follow the manufacturer's instructions for application rates and contact times. Typically, you'll need to soak the stone in the sanitizer solution for a specified duration, often around 30 minutes. Ensure the entire surface is covered, paying extra attention to joints and crevices.

Rinse Again: After sanitization, rinse the stone thoroughly with hot water to remove any residual disinfectant. This step is crucial to prevent any chemical residue from affecting the beer's taste. Use a high-pressure spray or a detailed cleaning brush to ensure all areas are cleaned.

Dry and Reassemble: Once the stone is completely dry, reassemble it according to your initial notes. Ensure all parts are correctly aligned and secured. Proper reassembly is essential to maintain the stone's functionality and prevent any potential leaks or damage.

Remember, consistent sanitation practices will contribute to the overall success of your brewing endeavors. By following these steps, you can create a clean and safe environment for your beer stone, resulting in better-tasting brews and a longer-lasting brewing apparatus.

Beer's Role in Colonoscopy Preparation: A Clear Liquid or Not?

You may want to see also

Frequently asked questions

Beer stone, also known as beer sediment or beer scum, is a layer of sediment that can accumulate at the bottom of your beer glass or in your brewing equipment. It is primarily composed of proteins, sugars, and other organic compounds that are left behind after the brewing process. This buildup can occur due to the slow evaporation of sugars and proteins, especially in environments with high humidity.

Cleaning beer stone from glassware is a simple process. Start by rinsing the glass under hot water to remove any loose particles. Then, use a small brush or a bottle cleaning tool to gently scrub the interior of the glass, paying extra attention to the bottom and sides where the stone tends to accumulate. You can also soak the glass in a mixture of warm water and a mild dish soap or a specialized beer glass cleaner for about 15-20 minutes to loosen the stone before scrubbing. Rinse thoroughly afterward to ensure no residue remains.

Yes, there are several natural methods to tackle beer stone. One popular approach is using white vinegar. Fill your glass with equal parts warm water and white vinegar, let it sit for a few minutes, and then rinse. The acidic nature of vinegar helps dissolve the stone. Alternatively, you can use a mixture of baking soda and warm water as a natural abrasive cleaner. Apply it to the stone-covered areas and scrub gently before rinsing.

Absolutely! Preventative measures are key to avoiding beer stone. After each use, rinse your glassware with hot water to remove any residual beer. Ensure you dry the glasses completely to eliminate moisture, as this can contribute to stone formation. Regularly clean your brewing equipment, especially if you notice any buildup, to prevent the accumulation of stone-causing substances. Maintaining a clean and dry environment for your glassware and brewing tools will significantly reduce the occurrence of beer stone.