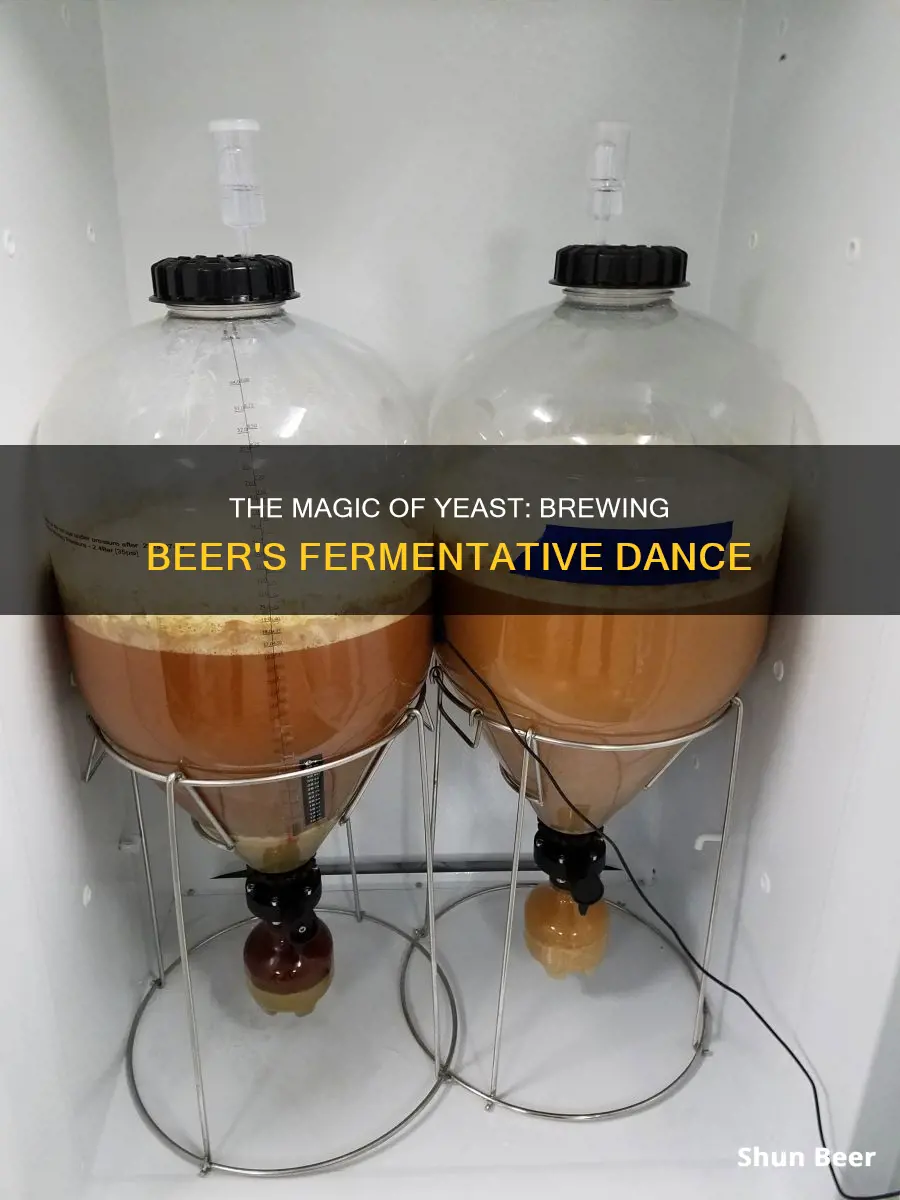

Yeast plays a crucial role in the fermentation process of beer, transforming sugars into alcohol and carbon dioxide. This intricate process begins with the yeast consuming sugars derived from malted grains, such as barley, and converting them into ethanol and carbon dioxide through a series of biochemical reactions. The yeast's metabolic activities not only produce alcohol but also contribute to the development of beer's unique flavors and aromas, making it an essential component in the art of brewing. Understanding the fermentation process is key to appreciating the complexity and diversity of beer styles.

What You'll Learn

- Yeast Strains: Different yeast strains produce unique beer flavors and aromas

- Sugar Metabolism: Yeast breaks down sugars, releasing alcohol and carbon dioxide

- Fermentation Stages: Primary and secondary fermentation shape beer's character and clarity

- Temperature Control: Optimal temperature ranges vary for yeast fermentation

- Inhibitors and Stress: Yeast stress can impact fermentation rate and beer quality

Yeast Strains: Different yeast strains produce unique beer flavors and aromas

Yeast strains play a pivotal role in the art of brewing, significantly influencing the character and quality of beer. Different strains of yeast possess distinct metabolic capabilities, which directly impact the flavor, aroma, and overall sensory experience of the final product. When yeast ferments beer, it undergoes a complex process of breaking down sugars derived from malted grains, primarily maltose, into simpler compounds, such as carbon dioxide and ethanol. This transformation is not just a biochemical reaction but an artful process that brewers carefully manipulate to achieve their desired beer styles.

The diversity in yeast strains is vast, each with its own unique characteristics. For instance, ale yeasts, such as Saccharomyces cerevisiae, are known for their high alcohol tolerance and ability to produce fruity esters, which contribute to the characteristic flavors of many ale styles. These esters can range from subtle fruity notes in a Belgian witbier to more pronounced, banana-like flavors in a Belgian tripel. On the other hand, lager yeasts, like Saccharomyces pastorianus, are characterized by their clean fermentation and the production of less esters, resulting in beers with a crisper, more neutral flavor profile, often found in pilsners and lagers.

The impact of yeast strains extends beyond flavor; it also affects the beer's aroma. For example, some yeast strains can produce higher levels of volatile compounds, such as isobutyraldehyde, which contributes to the characteristic "banana" or "clove" aromas in certain Belgian ales. Other strains may produce different aldehydes or ketones, leading to more complex and varied aromatic profiles. The choice of yeast can also influence the beer's mouthfeel, carbonation, and overall finish, making it a critical component in the brewer's toolkit.

Understanding the nuances of different yeast strains allows brewers to craft beers with specific characteristics, catering to diverse consumer preferences. For instance, the use of specialty yeast strains can create unique beer styles, such as the fruity, spicy notes of a Belgian lambic or the robust, earthy flavors of a Belgian strong ale. Each strain offers a distinct fermentation profile, affecting the beer's alcohol content, color, and clarity. Moreover, the interaction between yeast and the beer's ingredients, such as hops and water, further complicates and enriches the flavor and aroma profiles.

In summary, yeast strains are the unsung heroes of the brewing process, contributing to the diversity and complexity of beer flavors and aromas. The art of selecting the right yeast strain for a specific beer style is a delicate balance of science and creativity, allowing brewers to produce beers that are not only delicious but also unique and memorable. This understanding of yeast's role in fermentation has led to the development of various brewing techniques and styles, making the world of beer a fascinating and ever-evolving realm.

The Legalities of Beer in To-Go Cups: A Guide

You may want to see also

Sugar Metabolism: Yeast breaks down sugars, releasing alcohol and carbon dioxide

Yeast plays a crucial role in the fermentation process of beer, and its ability to break down sugars is at the heart of this transformation. When yeast encounters the sugars present in the wort (the sugary liquid extracted from malted grains), it initiates a metabolic pathway that is both fascinating and essential to the brewing craft. This process is a prime example of how microorganisms can be harnessed to create desired outcomes in food and beverage production.

The sugar metabolism of yeast is a complex biochemical reaction. Yeast cells possess the unique ability to convert sugars, primarily maltose, into simpler molecules through a process called fermentation. This is in contrast to other organisms that require oxygen for energy production, as yeast is an anaerobic microorganism. In the absence of oxygen, yeast employs a series of enzymes to break down the complex sugars into smaller, more manageable units.

At the core of this process is the enzyme amylase, which is present in the yeast cells. Amylase catalyzes the breakdown of maltose, a disaccharide formed by two glucose molecules, into two molecules of glucose. This initial step is crucial as it provides the yeast with the necessary energy source for further metabolic activities. As the yeast ferments, it releases carbon dioxide as a byproduct, which is why you might notice a slight fizzing or bubbling during the brewing process.

The subsequent steps involve the conversion of glucose into two molecules of ethanol (alcohol) and carbon dioxide. This is achieved through a series of reactions in the yeast's metabolic pathway, including glycolysis, the Krebs cycle, and the electron transport chain. In glycolysis, glucose is broken down into pyruvate, which is then converted into ethanol and carbon dioxide in the presence of specific yeast enzymes. This intricate dance of biochemical reactions results in the production of the beloved alcoholic beverage we know as beer.

Understanding the sugar metabolism of yeast is fundamental to the art of brewing. Brewers carefully select yeast strains and control fermentation conditions to influence the flavor, aroma, and overall character of the beer. Different yeast strains have varying sugar fermentation capabilities and alcohol tolerances, allowing brewers to create a wide range of beer styles, from crisp lagers to rich stouts. This process highlights the intricate relationship between microorganisms and the creation of diverse, flavorful beverages.

Fermentation's Fiery Effect: Unlocking Heat in Beer

You may want to see also

Fermentation Stages: Primary and secondary fermentation shape beer's character and clarity

The process of fermentation is a crucial step in brewing beer, and it involves the transformation of sugars into alcohol and carbon dioxide through the action of yeast. This intricate process can be divided into two main stages: primary and secondary fermentation, each contributing uniquely to the beer's final character and clarity.

Primary Fermentation: This initial stage is where the magic begins as yeast consumes the sugars present in the wort (the sugary liquid extracted from malted grains). The yeast strains used for brewing are typically ale or lager yeasts, each with distinct characteristics. During primary fermentation, the yeast ferments the wort's sugars, producing alcohol and carbon dioxide as byproducts. This stage is critical as it determines the beer's initial flavor and aroma profile. Ale yeasts, for instance, tend to create fruity and estery notes, while lager yeasts produce cleaner, crisper flavors. The duration of primary fermentation can vary, typically lasting 5 to 14 days, depending on the yeast type and the desired beer style.

As the primary fermentation progresses, the beer's clarity begins to take shape. The yeast's activity causes the formation of sediment, which can include dead yeast cells, proteins, and other solids. This sediment is not harmful but can affect the beer's appearance. After primary fermentation, the beer is often transferred to a secondary fermenter, where the yeast continues to work on any remaining sugars and contributes to the beer's final maturation.

Secondary Fermentation: This stage is an optional step but is highly influential in refining the beer's character. In secondary fermentation, the beer is allowed to rest and mature, often with the addition of dry hops or other ingredients to enhance flavor and aroma. The yeast's activity continues, but at a slower pace, allowing for subtle flavor developments. This stage is particularly important for styles like IPAs, where a complex, hop-forward character is desired. The secondary fermentation can last anywhere from a few days to several weeks, during which the beer's clarity may improve as the sediment settles.

The primary and secondary fermentation stages are interconnected, as the yeast's activity during the first phase sets the foundation for the beer's style and character. The choice of yeast and fermentation management significantly impact the beer's final attributes, including its clarity. Proper yeast management and fermentation techniques are essential to achieving the desired beer quality, ensuring a consistent and desirable product.

The Ultimate Guide to Toppings for Beer Bread: A Cheesy Delight

You may want to see also

Temperature Control: Optimal temperature ranges vary for yeast fermentation

Temperature control is a critical aspect of the beer-making process, especially during yeast fermentation. Yeast, the microscopic organisms responsible for converting sugars into alcohol and carbon dioxide, are highly sensitive to temperature changes. The optimal temperature range for yeast fermentation can vary depending on the specific yeast strain and the desired beer style.

For most ale yeasts, the ideal fermentation temperature range is between 65°F and 75°F (18°C to 24°C). At these temperatures, the yeast metabolizes sugars efficiently, producing a well-balanced beer with the desired flavor and aroma profiles. Maintaining this temperature range is crucial, as deviations can lead to off-flavors and aromas. For example, temperatures too low may result in a slow fermentation process, while temperatures too high can cause the yeast to become stressed, leading to a loss of flavor compounds and potential off-flavors like esters or ethyl acetate.

In contrast, lager yeasts, commonly used in the production of pale lagers, typically require a slightly lower temperature range of 50°F to 60°F (10°C to 15°C). This cooler temperature range allows for a slower fermentation process, which helps to develop the clean, crisp character associated with lagers. Lower temperatures also slow down the production of higher alcohols, reducing the risk of off-flavors.

It's important to note that temperature control is not just about setting the right range but also about maintaining consistency. Fluctuations in temperature can disrupt the yeast's metabolic processes and affect the beer's quality. Therefore, brewers often use various techniques to regulate temperature, such as using insulated fermenters, temperature-controlled fermentation chambers, or even external cooling systems to keep the fermentation environment stable.

Additionally, understanding the specific requirements of different yeast strains is essential. Some yeasts, like Brettanomyces, which are often used in wild ale production, thrive at higher temperatures around 70°F to 75°F (21°C to 24°C). These yeasts can contribute unique flavors and aromas to the beer, but their temperature preferences differ from those of ale and lager yeasts.

In summary, temperature control is a delicate balance in beer brewing, especially during yeast fermentation. Different yeast strains have varying optimal temperature ranges, and maintaining these ranges is crucial for producing high-quality beer with the desired characteristics. Brewers must be attentive to temperature fluctuations and employ appropriate techniques to ensure a successful fermentation process.

Uncorking the Truth: Can Beer Cause Septic System Issues?

You may want to see also

Inhibitors and Stress: Yeast stress can impact fermentation rate and beer quality

Yeast stress is a critical factor in the fermentation process of beer, and it can significantly impact the final product's quality and characteristics. When yeast undergoes stress, it can lead to various physiological changes that affect its ability to ferment sugars efficiently. One of the primary concerns is the presence of inhibitors, which are substances that can disrupt the yeast's metabolic processes and hinder fermentation. These inhibitors can be naturally occurring compounds in the malt or hops or added during the brewing process to control fermentation.

Inhibitors, such as alpha-amylase inhibitors and beta-glucanase inhibitors, can interfere with the yeast's ability to break down complex carbohydrates like starches and sugars. For example, alpha-amylase inhibitors can prevent the yeast from effectively converting maltose, a disaccharide, into fermentable sugars, leading to a slower fermentation rate. Similarly, beta-glucanase inhibitors might hinder the yeast's ability to produce the necessary enzymes to break down complex sugars, resulting in a reduced fermentation efficiency. These inhibitors can cause a delay in the fermentation process, affecting the beer's overall flavor, aroma, and alcohol content.

Stress can also arise from various environmental factors during the brewing process. High temperatures, for instance, can induce yeast stress, causing a decrease in fermentation rate and an increase in the production of off-flavors and aromas. Yeast is generally more sensitive to temperature changes, and extreme temperatures can denature enzymes, disrupt cell membranes, and alter the yeast's metabolic pathways. This stress may lead to a slower fermentation or even the production of defective beer.

Additionally, the presence of oxygen during fermentation can cause stress, as yeast requires a low-oxygen environment to function optimally. Oxygen exposure can lead to the production of higher levels of off-flavors and may also affect the yeast's ability to reproduce and grow, resulting in a slower fermentation process. Brewers often take measures to minimize oxygen contact with the yeast, such as using yeast starters or ensuring proper aeration control during fermentation.

Understanding and managing yeast stress is crucial for brewers to maintain consistent beer quality. By recognizing the impact of inhibitors and environmental stressors, brewers can implement strategies to mitigate these issues. This may include adjusting water chemistry, controlling temperature, using specific yeast strains, or adding specific nutrients to the wort to support yeast health and optimize fermentation performance. Effective management of yeast stress ensures that the yeast can efficiently ferment the sugars, resulting in a high-quality beer with the desired flavor profile and characteristics.

Troubleshooting Stuck Kolsch: Revive Your Fermentation with These Tips

You may want to see also

Frequently asked questions

Yeast is a crucial microorganism in the brewing process, responsible for converting sugars derived from malted grains into alcohol and carbon dioxide. This process, known as fermentation, is essential for producing alcoholic beverages like beer.

During fermentation, yeast consumes the sugars present in the wort (the liquid extracted from malted grains) and produces ethanol (alcohol) and carbon dioxide as byproducts. This process typically occurs in two stages: the primary fermentation, where the majority of the alcohol is produced, and the secondary fermentation, which refines the beer's flavor and clarity.

Brewers use various yeast strains for different beer styles. Ale yeasts, such as Saccharomyces cerevisiae, are commonly employed for their ability to ferment at higher temperatures, resulting in a faster fermentation process. Lager yeasts, like Saccharomyces pastorianus, are used for their slower fermentation at cooler temperatures, producing a cleaner and crisper beer profile.

Top-fermenting yeasts, like ale yeasts, ferment near the surface of the wort, giving them their name. They produce a fruity and estery flavor profile, which is characteristic of styles like wheat beers and certain ales. Bottom-fermenting yeasts, used in lagers, ferment at lower temperatures near the wort's surface, resulting in a cleaner, crisper beer with less fruitiness.