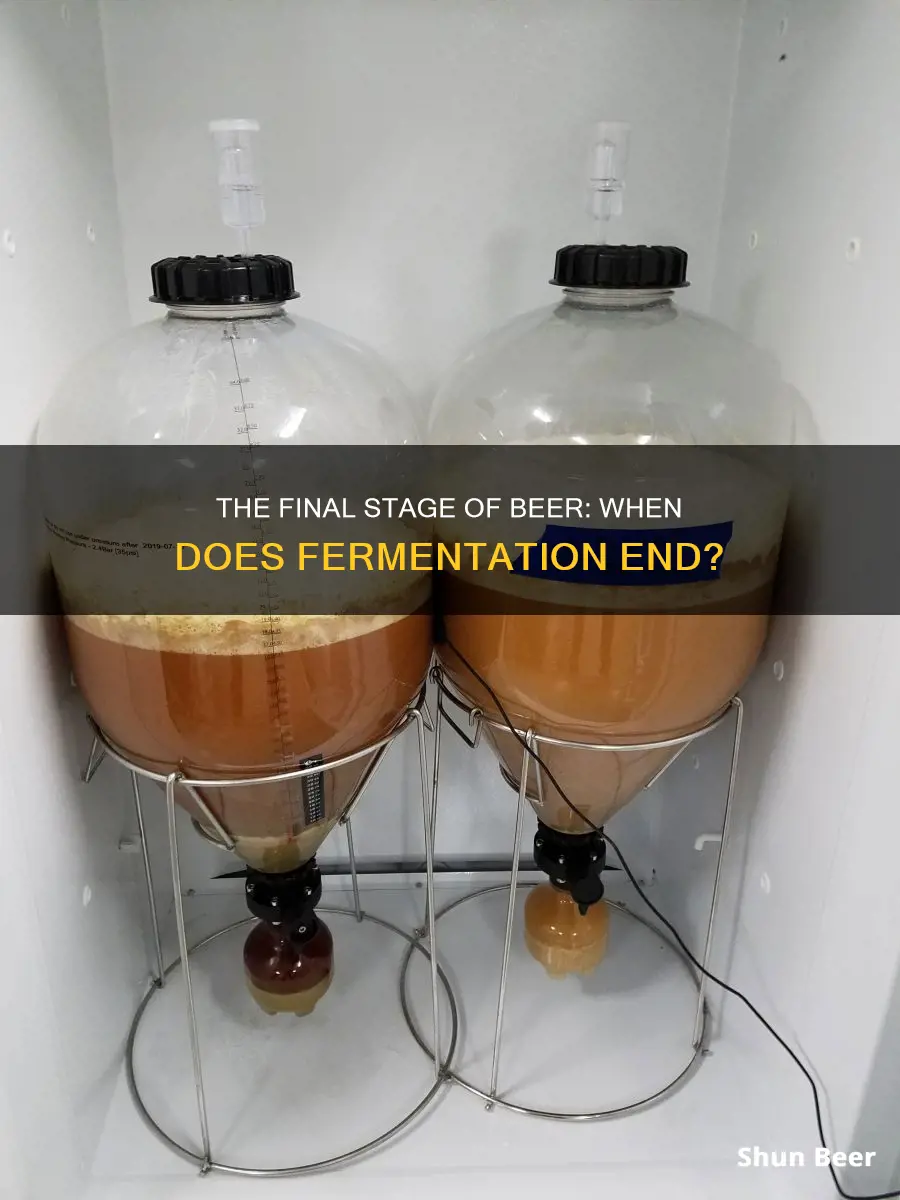

When does beer fermentation end? Understanding the duration of fermentation is crucial for achieving the desired flavor and character in your beer. The process of fermentation, where yeast converts sugars into alcohol and carbon dioxide, can vary significantly depending on the style of beer, yeast type, and brewing techniques. While some beers may ferment within a few days, others can take several weeks to fully mature. This article will explore the factors influencing fermentation duration and provide insights into how to optimize the process for your specific beer recipe.

What You'll Learn

- Temperature Control: Fermentation ends when temperature is consistent and optimal, usually around 65°F (18°C)

- Alcohol Content: High alcohol levels signal fermentation completion, typically above 8% ABV

- Carbonation: Carbon dioxide production slows, indicating fermentation's end

- Clarity: Cloudy beer suggests ongoing fermentation; clear beer indicates completion

- Sulfur Compounds: Reduced sulfur levels in beer mark fermentation's end

Temperature Control: Fermentation ends when temperature is consistent and optimal, usually around 65°F (18°C)

The process of beer fermentation is a delicate dance of temperature and time, and achieving the right conditions is crucial for a successful brew. When it comes to the end of fermentation, temperature control is the key factor that determines the quality and character of the final product.

During the fermentation process, yeast consumes sugars and produces alcohol and carbon dioxide. This transformation is highly temperature-sensitive, and maintaining a consistent temperature is essential. As the yeast works its magic, it thrives in a specific temperature range, typically around 65°F (18°C). At this temperature, the yeast remains active and continues to convert sugars, ensuring a robust and flavorful beer.

The end of fermentation is marked by a stable temperature reading. If the temperature fluctuates, it can lead to off-flavors and a less-than-desirable beer profile. Brewers aim for a consistent environment to encourage the yeast to complete its work thoroughly. This consistency ensures that the yeast has fully converted the available sugars, resulting in a balanced and well-rounded beer.

Monitoring temperature is a critical aspect of brewing. Brewers often use specialized equipment to maintain precise control over the fermentation vessel's temperature. This attention to detail allows for the creation of beers with distinct characteristics, from crisp and refreshing lagers to rich and complex stouts.

In summary, the end of beer fermentation is signaled by a stable temperature, ideally around 65°F (18°C). This optimal condition encourages the yeast to perform its role effectively, resulting in a high-quality, flavorful beer. Achieving and maintaining this temperature is an art that brewers master to create exceptional beverages.

Fermentation: The Heart of Beer's Magic

You may want to see also

Alcohol Content: High alcohol levels signal fermentation completion, typically above 8% ABV

The end of the fermentation process in beer production is a crucial moment, and it's primarily indicated by the alcohol content reaching a certain threshold. When brewing beer, the goal is to achieve a specific alcohol by volume (ABV) percentage, which signifies the completion of fermentation. Typically, this target is set above 8% ABV, as this level of alcohol is often associated with a fully fermented beer.

During fermentation, yeast consumes the sugars present in the wort (the sugary liquid extracted from malted grains) and converts them into alcohol and carbon dioxide. As the yeast works its magic, the alcohol content in the beer gradually increases. Brewers carefully monitor this process to ensure the beer reaches the desired alcohol level. When the fermentation nears its end, the yeast's activity slows down, and the alcohol concentration stabilizes at or above the target ABV.

At this stage, it's essential to distinguish between primary and secondary fermentation. Primary fermentation occurs in the brew kettle, where the yeast ferments the wort to the desired alcohol level. Secondary fermentation, on the other hand, is an optional step where the beer is transferred to a new vessel, allowing for further maturation and flavor development. The alcohol content during secondary fermentation should remain stable, indicating that the beer is fully fermented.

To determine if fermentation is complete, brewers often use a hydrometer, a simple tool that measures the specific gravity of the beer. The specific gravity reading will gradually decrease as the yeast consumes the remaining sugars, and it stabilizes when fermentation ends. Additionally, a refractometer can be used to measure the sugar content directly, and a significant drop in sugar levels confirms the completion of fermentation.

It's worth noting that the fermentation process can vary depending on the beer style and brewing techniques. Some beers may require longer fermentation periods, while others might benefit from extended maturation. However, the alcohol content remaining above 8% ABV is a reliable indicator that the beer has reached its desired state and is ready for packaging or further aging.

Chill Your Beer: The Ultimate Guide to Storage

You may want to see also

Carbonation: Carbon dioxide production slows, indicating fermentation's end

The process of carbonation in beer is a fascinating aspect of fermentation, and understanding when it slows down can be crucial for brewers to know when their beer is ready. Carbon dioxide (CO2) production is a key indicator of fermentation progress, and its gradual decrease signals the end of the fermentation process. Here's a detailed look at this phenomenon:

As yeast consumes sugars and converts them into alcohol and CO2, the beer becomes carbonated. Initially, you'll notice a steady increase in CO2 levels, which is a sign of active fermentation. However, this rate of CO2 production will eventually slow down. The slowdown is a natural part of the fermentation cycle and indicates that the yeast is nearly depleted of the available sugars, and the fermentation process is coming to a close. This reduction in CO2 production is a clear sign that the beer is fermenting and is ready for packaging or further aging.

Brewers often use this carbonation data to determine the optimal time to bottle or keg their beer. By monitoring the CO2 levels, they can ensure that the beer is properly carbonated without over-carbonation, which can lead to a sharp, unpleasant taste. The goal is to achieve a balanced carbonation level that enhances the beer's flavor and mouthfeel.

Additionally, the slowdown in CO2 production can also indicate the beer's stability. Once fermentation ends, the beer's carbonation stabilizes, and it becomes ready for consumption. This stability is crucial for maintaining the beer's quality and ensuring a consistent drinking experience.

Understanding the carbonation profile of your beer is an essential skill for any homebrewer or professional brewer. It allows for precise control over the fermentation process, ensuring that the beer is carbonated to perfection. By paying close attention to the CO2 production rates, you can fine-tune your brewing techniques and consistently produce high-quality, well-carbonated beers.

The Surprising Reason to Sift Beer: Uncovering a Hidden Secret

You may want to see also

Clarity: Cloudy beer suggests ongoing fermentation; clear beer indicates completion

The visual clarity of a beer can provide valuable insights into its fermentation process. Cloudy beer often indicates that the fermentation is still ongoing, while a clear beer suggests that the fermentation has reached its conclusion. This phenomenon is primarily due to the yeast's activity and the subsequent changes in the beer's composition.

During fermentation, yeast consumes sugars and produces alcohol and carbon dioxide. This process creates a cloudy appearance in the beer, especially if the yeast is active and present in large quantities. As the yeast works its magic, it transforms the beer's composition, leading to the formation of various compounds that contribute to the overall flavor, aroma, and texture. The longer the fermentation process, the more complex and nuanced the beer's characteristics tend to become.

When the fermentation nears its end, the yeast's activity slows down, and the beer begins to clear up. This is because the yeast has consumed most of the available sugars, and the remaining yeast cells start to settle at the bottom of the fermentation vessel. As a result, the beer's appearance becomes clearer, and any remaining yeast particles or sediment may be visible near the container's surface.

It's important to note that the clarity of a beer can also depend on other factors, such as the type of yeast used, the brewing process, and the specific ingredients in the beer. Some beers, like wheat beers or certain styles with higher yeast content, are naturally cloudier and may remain so even after fermentation. In contrast, highly filtered or clarified beers might appear clear, even if the fermentation process is not yet complete.

Understanding the relationship between beer clarity and fermentation progress can be beneficial for both brewers and beer enthusiasts. Brewers can use this knowledge to monitor the fermentation process and ensure the desired flavor and quality. Beer lovers can appreciate the nuances of different beer styles and the art of brewing by observing the beer's clarity and its evolution over time.

Mastering Beer Gravity: A Guide to Fermentation Monitoring

You may want to see also

Sulfur Compounds: Reduced sulfur levels in beer mark fermentation's end

The end of beer fermentation is a crucial moment in the brewing process, and one of the key indicators is the reduction in sulfur compounds. Sulfur is an essential element in the brewing process, but excessive levels can negatively impact the beer's flavor and aroma. As fermentation progresses, yeast consumes sugars and produces alcohol and carbon dioxide, but it also generates sulfur compounds as a byproduct. These compounds, including hydrogen sulfide and sulfur dioxide, contribute to the beer's unique character, but in excess, they can result in off-flavors and odors, such as a "skunky" or "eggy" smell.

When the fermentation process nears its conclusion, the yeast's activity slows down, and the production of sulfur compounds decreases. This reduction in sulfur levels is a clear sign that the yeast has exhausted its available nutrients and is no longer actively metabolizing sugars. Brewers often monitor sulfur dioxide (SO2) levels to determine when fermentation is complete. As the yeast population diminishes, the SO2 levels in the beer gradually decrease, providing a visual and measurable way to assess the end of fermentation.

The timing of this sulfur reduction can vary depending on the brewing style and yeast strain used. For example, high-alcohol beers or those with specific yeast strains may exhibit a slower fermentation and a more gradual decrease in sulfur levels. Conversely, some yeast strains are known for their rapid fermentation and a more rapid drop in sulfur compounds. Brewers often aim for a specific sulfur dioxide level as a target, indicating that the beer has reached a balanced and desirable state.

At this stage, it is essential for brewers to take precise measurements and make informed decisions. They may adjust the fermentation temperature or add specific ingredients to control the sulfur levels and ensure the beer's quality. Once the sulfur levels are at the desired level, the beer is considered ready for packaging or further conditioning.

In summary, the reduction in sulfur compounds serves as a vital indicator of the end of beer fermentation. Brewers can closely monitor sulfur dioxide levels to determine when the yeast has completed its work, allowing them to produce beers with the desired flavor profiles and aromas. This process requires careful attention to detail and an understanding of the complex interactions between yeast, sugars, and sulfur compounds during fermentation.

The Sweet & Bitter: Exploring Orange-Infused Beer Styles

You may want to see also

Frequently asked questions

The fermentation of beer is a continuous process that can take several weeks to complete. It is generally considered complete when the yeast has consumed most of the available sugars in the wort and the beer has reached a stable, desired alcohol content. However, it's important to note that fermentation can be a gradual process, and some yeast strains may continue to ferment at a very slow rate even after the beer has been packaged.

Several factors can affect the fermentation time: yeast type, starting temperature, wort composition, yeast health, and fermentation vessel temperature control. Different yeast strains have varying fermentation profiles, with some being faster and more robust, while others may take longer and be more sensitive to temperature changes.

There are a few methods to check if fermentation is finished: measuring gravity with a hydrometer, using a fermentation thermometer to monitor temperature drops, and observing the beer's clarity. When the beer's gravity stabilizes and no longer decreases, and the temperature drops consistently, it indicates that fermentation is likely complete.

Yes, fermentation can continue in the final packaging stage, especially with certain yeast strains. This is known as "lagering" for lagers or "conditioning" for ales. During this phase, the beer may still undergo a slow fermentation process, contributing to flavor development and carbonation.

Incomplete fermentation can lead to various issues. The beer may have an off-flavor, higher than expected alcohol content, or insufficient carbonation. It can also result in the presence of live yeast, which can cause further fermentation and potential contamination, affecting the beer's quality and stability. Proper yeast management and monitoring are crucial to ensure a successful fermentation process.